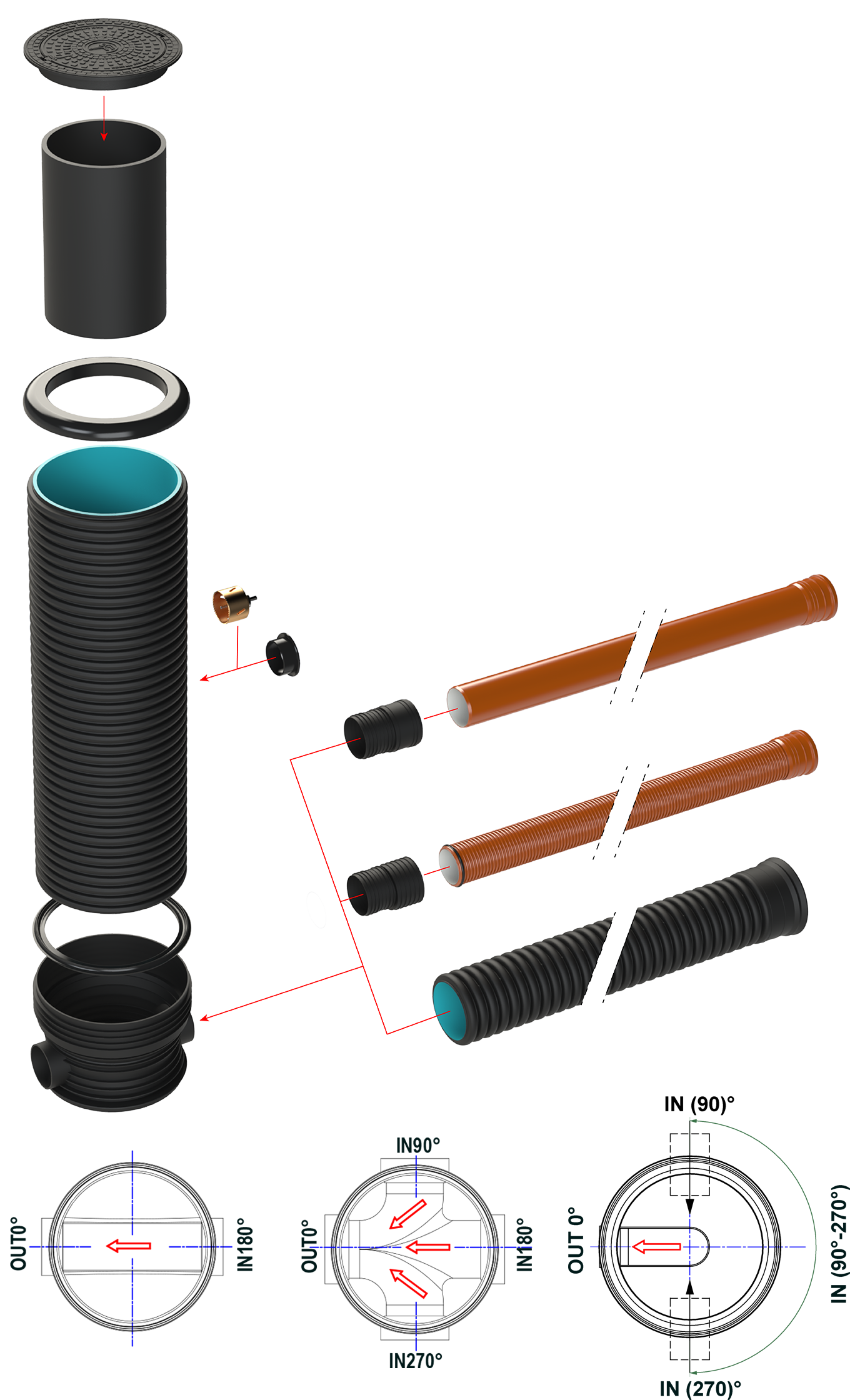

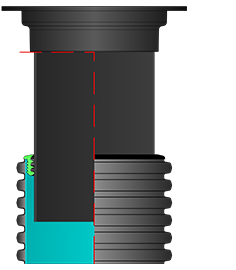

Inspection chamber CSL 600.500

With corrugated pipe shaft and telescopic pipe

Connections DN/OD 160, 200, 250, 315 mm

Inspection chamber DN/ID 600 [mm] with telescopic pipe and D400 class cast iron cover.

- Base connections at 90° .. 270°

- Connection DN/OD 110 .. 315 [mm]

- Telescopic pipe: DN 500 [mm]

-

Advantages

Long service life (>50 years)

Flexibile for movements in soil (no cracking of the manhole)

Water-tightness > 0.5 bar, watertight materials

Resistant to aggressive environment, no corrosion

The diameter of access hole allows convenient and quick maintenance of sewerage networks

-

Recommended application

Yards of multi-storey dwellings

Parking places and vehicle storage areas

Pavements, pedestrian and bicycle paths

Stadiums and sport complexes

Road construction (with and without transport load)

-

Chamber components

Type 1B 3BL 1C Connections OUT 0° / IN 180° OUT 0°

IN 135° / 180° / 225°OUT 0° DN/OD [mm] 160 / 200 / 315 160 / 200 / 250 160 / 200 / 250 / 315 By using 3BL type base and end cap(s) it is possible to make 1BB, 2BL, 2BT type base configuration

-

Technical information

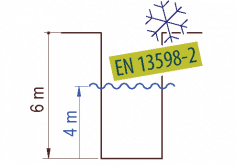

Installation depth

Minimum instalation depth: 1.25 m

Maximum installation depth is up to 6.0 m, if the ground water level is 2.0 m from the surface. If the ground water level is 0.0 m from the surface, the maximum installation depth is 5.0 m, according to the requirements of EN 13598-2 standard

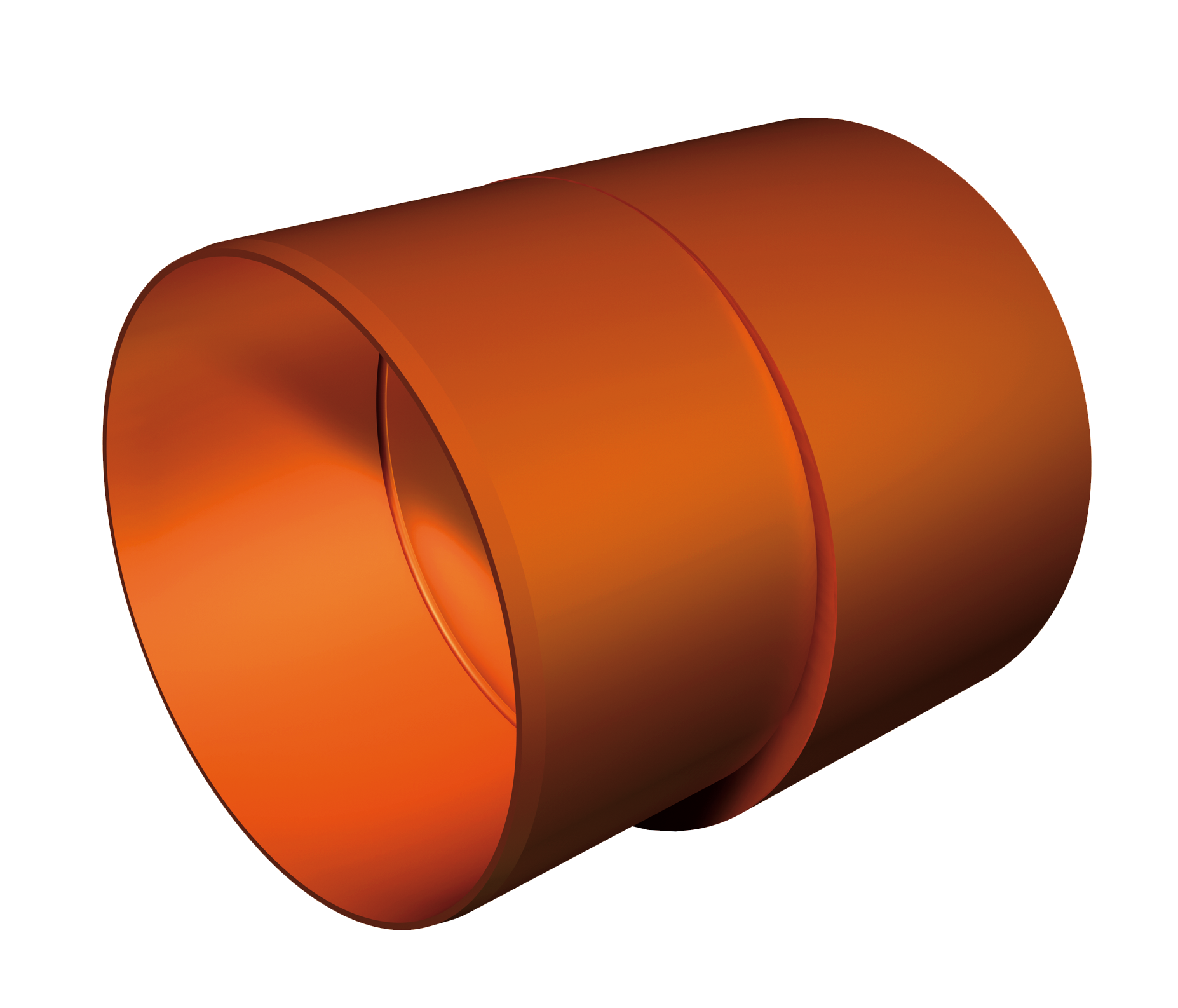

Chamber base

Polypropylene (PP) base of chamber DN 600 mm correspond to the requirements of EN 13598-1, EN 13598-2 and EN 476

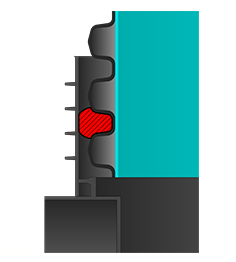

Sealing ring

Sealing ring DN 600 mm and rubber cuff DN 600/500 mm correspond to the requirements of EN 681-1/A3 and EN 1277 standards

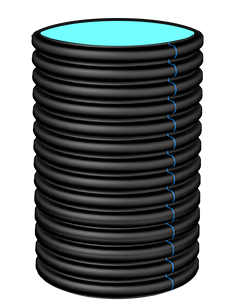

Chamber shaft

Height-adjustment corrugated PP double-wall shaft DN/ID 600 mm conform to the requirements of EN 13476-3 and EN 14802 standards

Telescopic pipe

Telescopic PE smooth-wall pipe DN/OD 500 mm, height 0.75 m, corresponds to the requirements of EN 12201-2 and EN 14802 standards

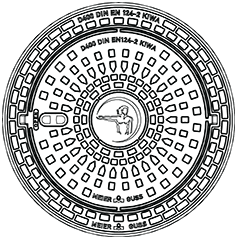

Chamber cover

Cast iron frame and cover, DN 500 mm, installation class D400 (40t) corresponds to the requirements of EN 124-2 standard

-

Drawings

.png)