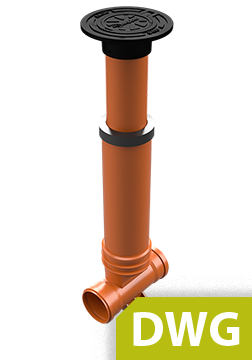

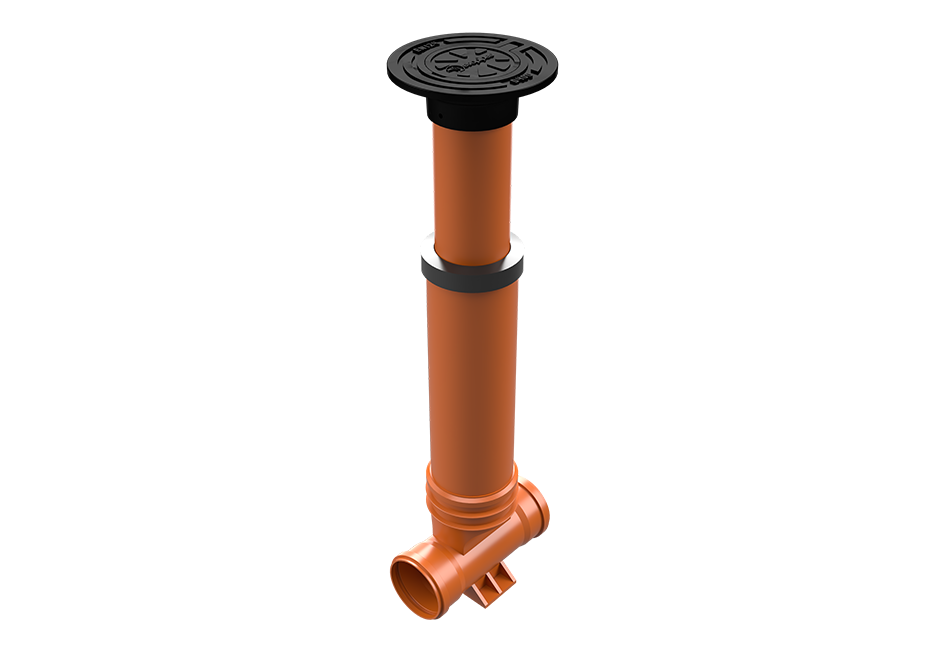

Inspection chamber CSS 200.160

Flow-through inspection chamber with telescopic pipe

Connections DN/OD 110, 160, 200 mm

Inspection chamber DN/OD 200 [mm] with telescopic pipe and D400 class cast iron cover.

- The base connection can be made at 180°

- Connection DN/OD 110 .. 200 [mm]

- Telescopic pipe: DN 160 [mm]

-

Advantages

Shorter construction period

Long service life (>50 years)

Flexible for movements in soil (no cracking of the chamber)

Water-tightness > 0.5 bar, watertight materials

Resistant to aggressive environment, no corrosion

-

Recommended application

Yards of multi-storey dwellings

Stadiums and sport complexes

Pavements, pedestrian and bicycle paths

-

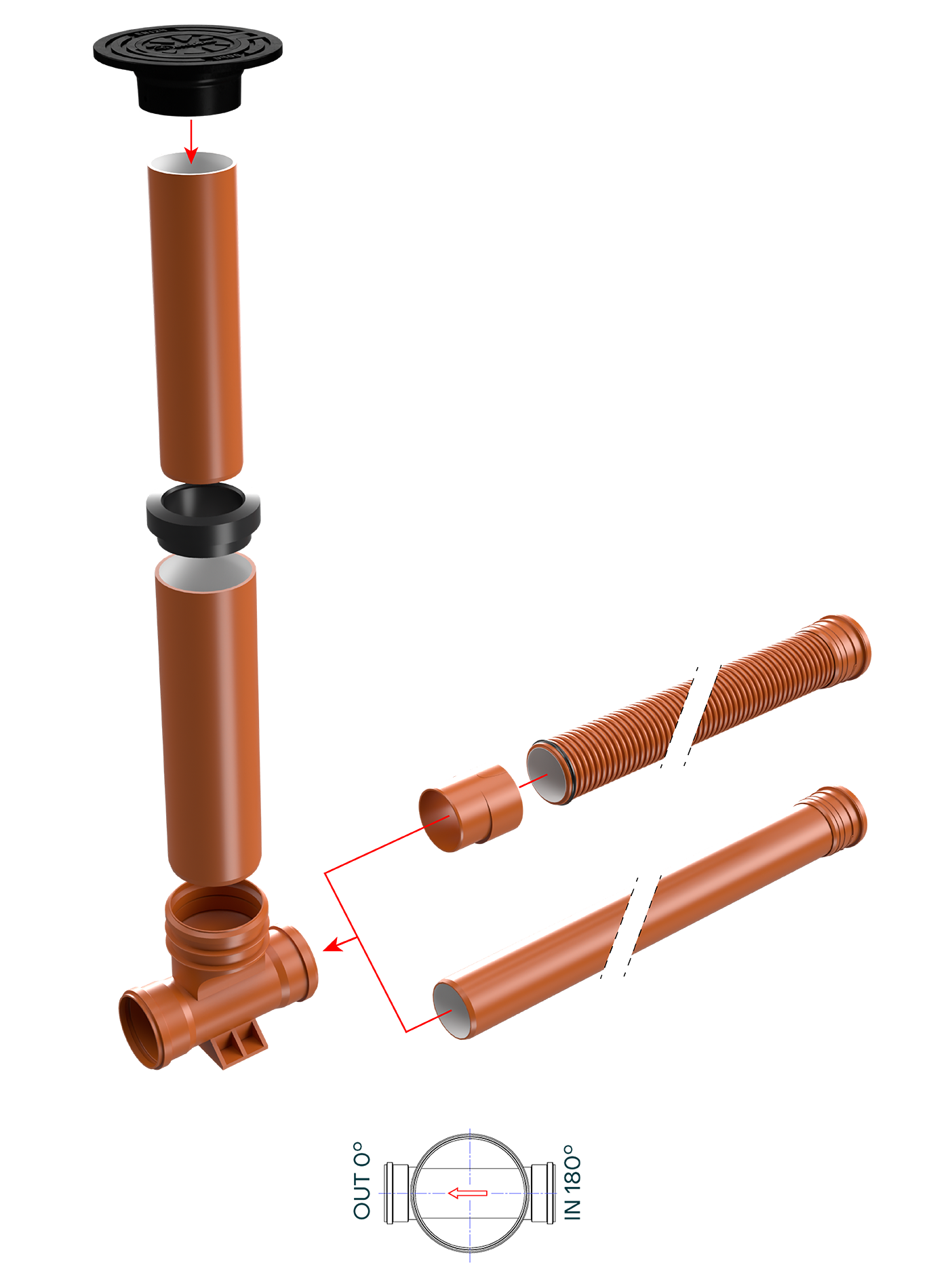

Chamber components

Connections OUT 0° IN 180° DN/OD [mm] 110 / 160 / 200 110 / 160 / 200 Chamber base with two connections -

Technical information

Chamber construction depth:

- Minimum installation depth: 0.7 [m]

- Maximum installation depth: 1.5 [m]

- Chamber application area code: U (for construction in subsoil outside building constructions)

- Chamber installation according to: EN 1610, CEN/TR 1046

Chamber covers:

- Round cast iron frame and cover, DN 160 [mm], installation class D400 (40t), corresponds to the requirements of EN 124 standard

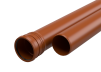

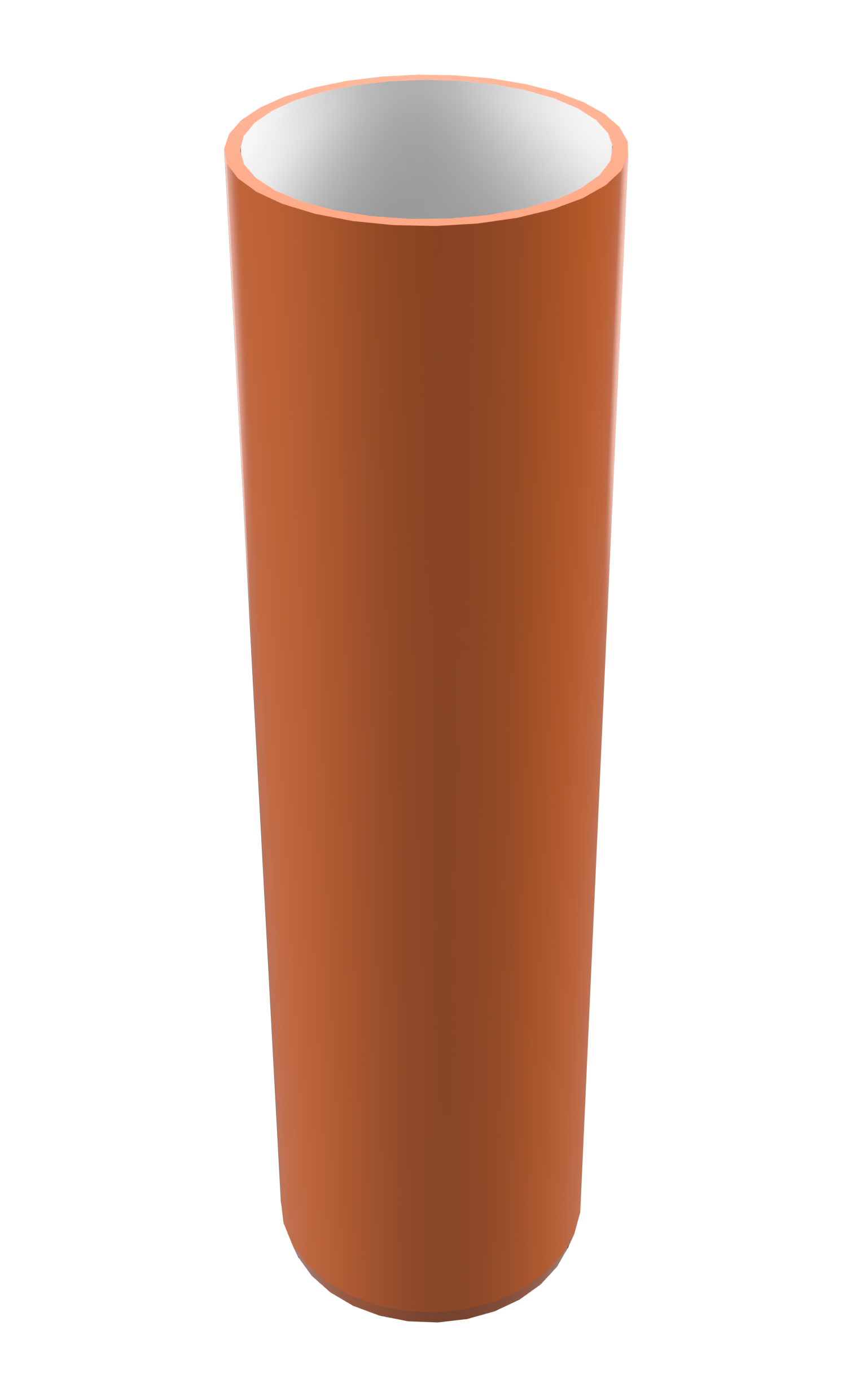

Telescopic section:

- PP smooth-wall telescopic pipe DN/OD 160 [mm], height 0.6 [m], corresponds to the requirements of EN 13476-2 standard

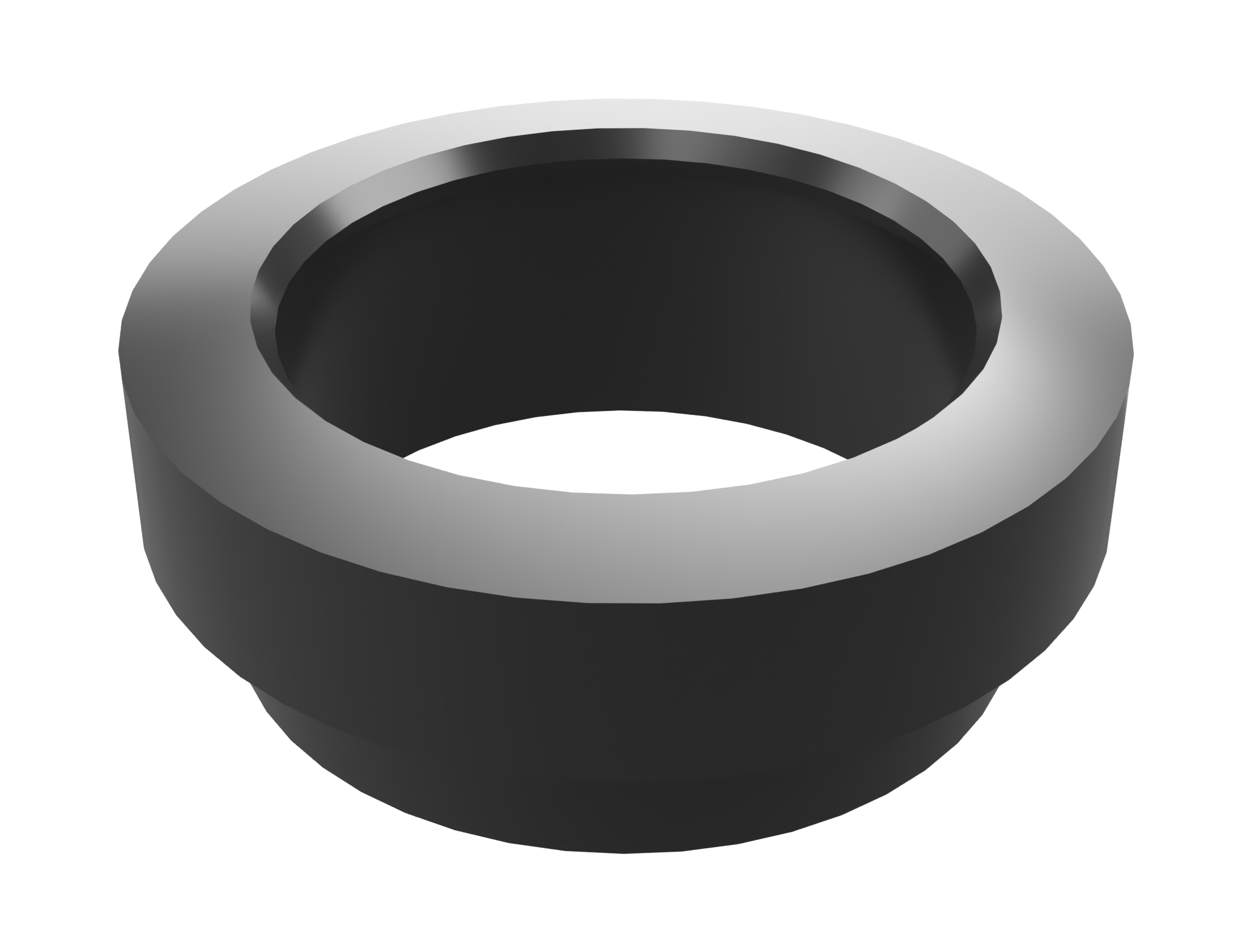

- Rubber cuff DN 200/160 corresponds to the requirements of EN 681-1/A3 and EN 1277 standards

Chamber shaft and base configurations:

- Polypropylene (PP) smooth-wall height-adjustment shaft DN/OD 200 [mm], corresponds to the requirements of EN 13476-2 standard

- PP base of flow-through chamber CRS DN 200 [mm] correspond to the requirements of EN 13598-2, EN 476 standards

Subject to ISO/TR 10358 and ISO/TR 7620, elements of the plastic chamber, as well as rubber sealing elements (rubber sealing rings and cuffs) are chemically resistant in pH 2 (acidic environment) and pH 12 (alkaline environment)

-

Drawings

-

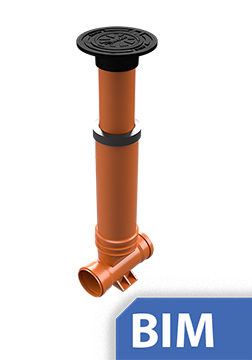

Revit BIM files