EVODUCT

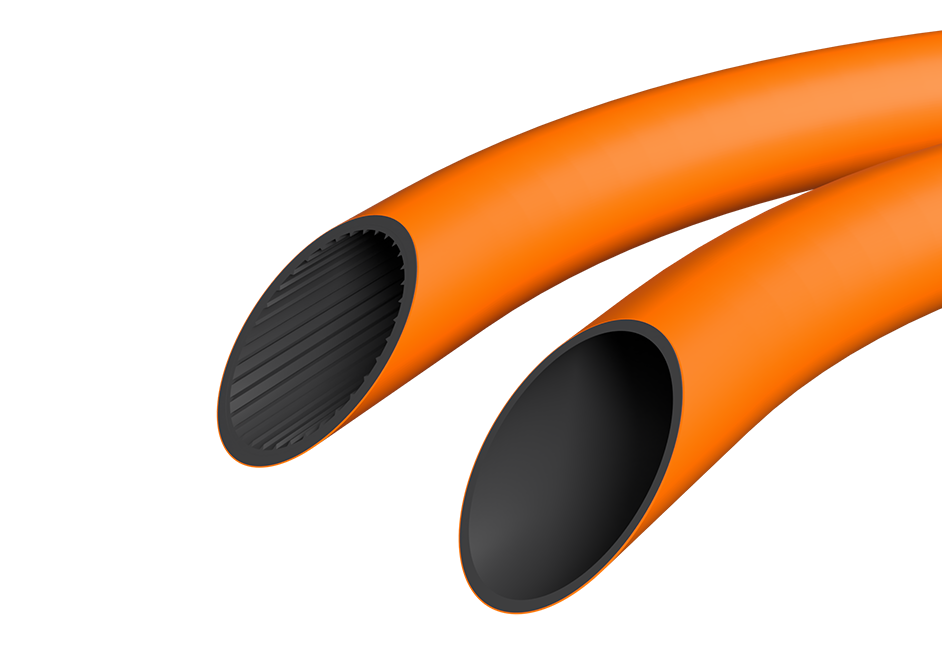

Optical cable pipes

Normal impact resistance, Compression strength: 750, DN/OD 25 .. 63 mm

When constructing ground-buried optical cable and communication cable systems, the best solution is to ensure the long-term protection of the cables with rigid plastic conduits. The cable protection pipes are manufactured in large and small rolls, and each roll is secured with polypropylene tape. The rolls are delivered on palettes.

- Available sizes: DN/OD 25 .. 63 [mm]

- Compression strength class: 750

These rigid, high-density polyethylene (HDPE) pipes come standard with a smooth outer surface and one of the following inner surfaces:

- STANDARD: smooth inner surface

- GROOVE: longitudinal grooved inner surface

-

Advantages

- Easy, convenient, and more cost-effective construction of cable networks and preparation for cable-pulling (with cord or blowing)

- Quick cable replacement without additional earthwork

- Couplers make easy coupling of pipes

- The length marks on the pipes allow determining the overall length of the installation

- High outer and inner pressure-resistance

- The materials used to ensure that the conduits are environment-friendly and feature a long-term resistance against the effects of the aggressive substances present in the soil

-

Recommended application

Protection of electrical systems near railway lines

The conduits can be buried directly in the soil, in concrete, or through water barriers, in concrete pipes, channels and blocks, along bridges and flyovers.

The conduits are used for the installation of optical fibre cables employing traditional installation methods - pulling with a cord or blowing.

-

Technical information

EVODUCT pipes are black (RAL 9005) or orange (RAL 2004), with 4 (every 90º) white single or double longitudinal lines along the entire length. They bear white thermal labelling located at 1 m intervals (minimum symbol height — 4 mm). The labelling includes information about the product and the name of the manufacturer. On request, pipes / longitudinal lines of any colour (according to RAL) can be manufactured. Custom-made labelling is also possible.

On request, EVODUCT pipes can be manufactured with a customer-specified thickness of the wall.

- Material: polyethylene (HDPE)

- Compression strength class- 750

- Impact resistance- N normal

- Temperature range from -25ºC to +90ºC

- Temperature shrinkage: ≤3% 110 ºC, 1 h (EN ISO 2505:2005)

EVODUCT STANDARD DN110 pipe outer color is red and inner color is black. Compression strength class: 1250N

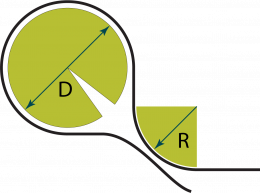

Pipe dimensions Dimensions DN25 DN32 DN32 DN40 DN40 DN50 DN50 DN63 DN63 Outer Ø [mm] 25 32 32 40 40 50 50 63 63 Inner Ø [mm] 20.4 27.6 26.0 34.0 32.6 44.0 40.8 55.8 51.4 Wall thickness [mm] 2.3 2.2 3.0 3.0 3.7 3.0 4.6 3.6 5.8 SDR class 11 13.6 11 13.6 11 17 11 17 11 Length [m] 500/1000 300 1000 1000 1000 500 500/750 400 600 Bend radius [≥ m] 0.5 0.64 0.64 0.8 0.8 1.0 1.0 1.26 1.26

R- Bend radius

D- Bend diameterInstallation of the cables by blowing, recommendable conditions:

- Air pressure range: 0.8–1.2 [MPa]

- Airflow rate: 10–12 [m³/min]

Max. allowable pulling force Nominal size 25 32 32 40 40 50 50 63 63 Wall thickness 2,3 2,2 3,0 3,0 3,7 3,0 4,6 3,6 5,8 Maximum allowable initial pulling force, kN Pulling time hours

t < 10h1,6 2,1 2,7 3,5 4,2 4,4 6,6 6,7 10,4 Pulling time hours

10h < t < 20h1,4 1,8 2,3 3 3,6 3,8 5,6 5,7 8,9 Pulling time hours

t > 20h1,2 1,5 2 2,6 3,2 3,3 4,9 5 7,8 -

Certificates