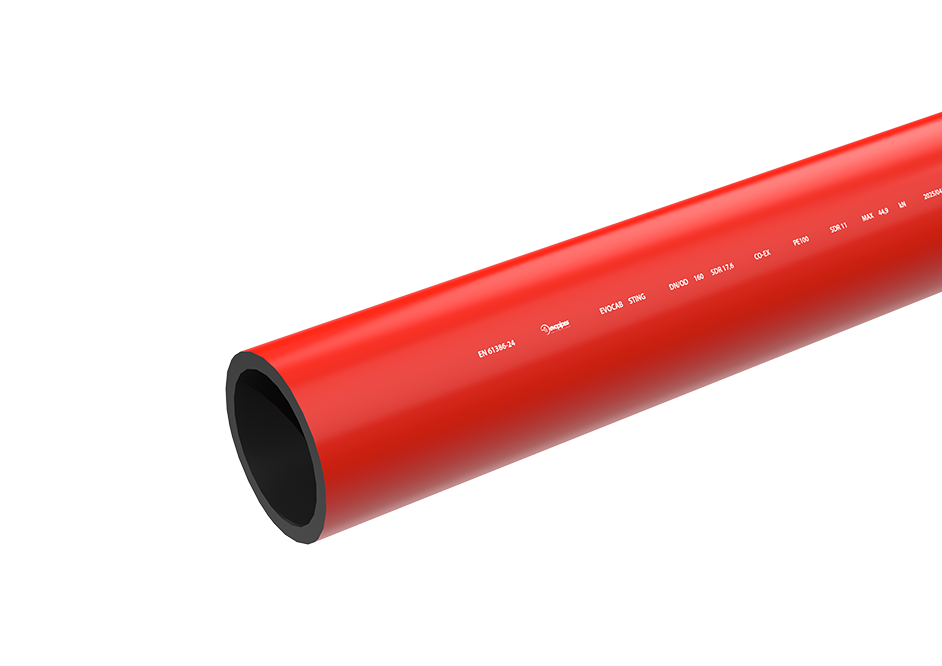

EVOCAB STING

Pipes for trenchless installations

Normal Impact resistance, Compression strength: 1250, DN/OD 50 .. 500 mm

EVOCAB STING cable protection pipes are made of high-density polyethylene (HDPE) and designed so that they can withstand loads caused by soil and vehicles.

STING type pipes have a smooth inner and outer surface. These pipes can be used to protect and insulate cables in underground installations made using the method of directional drilling. The cable protection pipes for trenchless installations are available in pieces of various lengths and in rolls.

- Available sizes: DN/OD 50 .. 500 [mm]

- Compression strength class: 1250

- SDR class: from 17.6 to 11*

- MRS class: 10

*can be specified on a request

-

Advantages

- Quicker, more convenient, and cost-efficient construction of cable networks using the method of horizontal directional drilling

- By using butt fusion method pipes are easy to interconnect

- The pipe marking also includes length marks to determine installation length

- The materials used to ensure that the conduits are environment-friendly and feature a long-term resistance against the effects of the aggressive substances present in the soil

- Cables can be quickly replaced without additional earthwork

-

Recommended application

Protection of electrical systems near railway lines

The STING pipes can be used to protect and insulate cables in underground installations made using the method of directional drilling. They are especially suitable for use in systems requiring a high compression strength, e.g. under roads, squares, etc.

By design, they are made for cable protection using the conventional method of installation – pulling by wire.

In some projects, depending on the technology of directional drilling, properties of the soil, angle of pulling, distance and depth of pulling, project-specific pipe with an adapted (custom) thickness of the wall can be ordered.

-

Technical information

The standard colour is red, with a white marking. Other colours are available on request.

- Material polyethylene (PE100)

- Compression strength class- 1250

- Impact resistance- N (normal)

- Temperature range -25ºC to +90ºC

- MRS class: 10

Pipe dimensions Dimensions DN50 DN63 DN75 DN90 DN110 DN125 DN160 DN200 DN250 DN280 DN315 DN400 DN500 DN560 DN630 Outer Ø [mm] 50 63 75 90 110 125 160 200 250 280 315 400 500 560 630 Inner Ø [mm] 42.6 53.6 63.8 79.2 96.8 110.8 141.8 177.2 224.4 248.2 279.2 354.6 443.2 496.6 558.6 SDR¹ class 13.6 13.6 13.6 17 17 17.6 17.6 17.6 17.6 17.6 17.6 17.6 17.6 17.6 17.6 Wall thickness [mm] 3.7 4.7 5.6 5.4 6.6 7.1 9.1 11.4 12.8 15.9 17.9 22.7 28.4 31.7 35.7 Length [m] 100 100 100 12/13.4/50/100 12/13.4/50/100 12/13.4/50/75 12/13.4 12/13.4 12/13.4 12/13.4 12/13.4 12/13.4 12/13.4 12/13.4 12/13.4 SDR¹ - other pipe sizes and SDR values available on request

EVOCAB STING pulling parameters:

The following values are informative and should be adjusted according to pulling conditions taking into account all the technical and specific aspects.

Max.admissible pulling force [kN] DN/OD Air temperature 20°C SDR17 / 17.6 SDR13.6 SDR11 50 4.4 5.4 5.9 63 7.1 8.6 10 75 10.4 12.2 15 90 14.4 * 21 110 21.4 * 31 125 27.3 * 41 140 33 * 51 160 44.9 * 66 180 55 * 84 200 70.3 * 104 225 90 * 131 250 109.4 * 162 280 132 * 204 315 174.1 * 258 355 212 * 326.5 400 269 * 415 450 341 * 526 500 421 * 648 560 528 * 814 630 668 * 1030 - If pulling lasts longer than 30 minutes, these values must be reduced by 10%

- if pulling lasts longer than 20 h, the values must be reduced by 25%

- In the case of additional bending loads, the corresponding reduction must be taken into account.

-

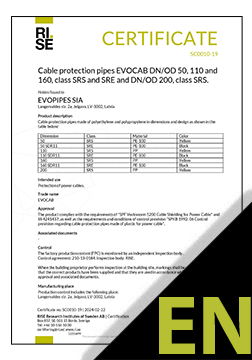

Certificates

The EVOCAB cable protection pipes are manufactured in compliance with standards:

- EN 61386-1:2018

- EN 61386-24:2011

Conformity:

- DIN 8074/8075

- GW 321 (by DVGW)