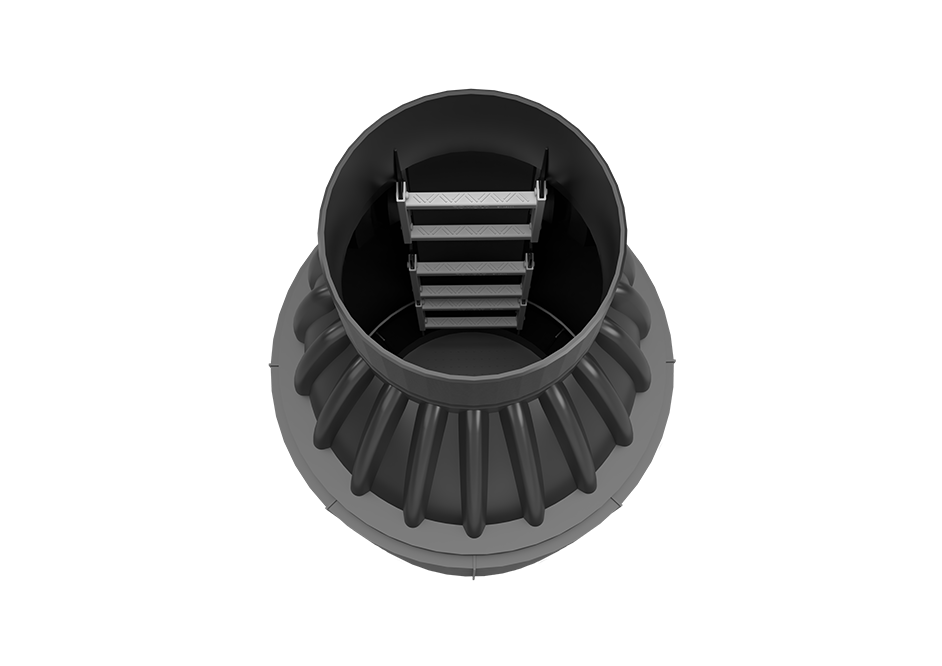

Manhole CSL 1000.625

With an injection moulded shaft rings

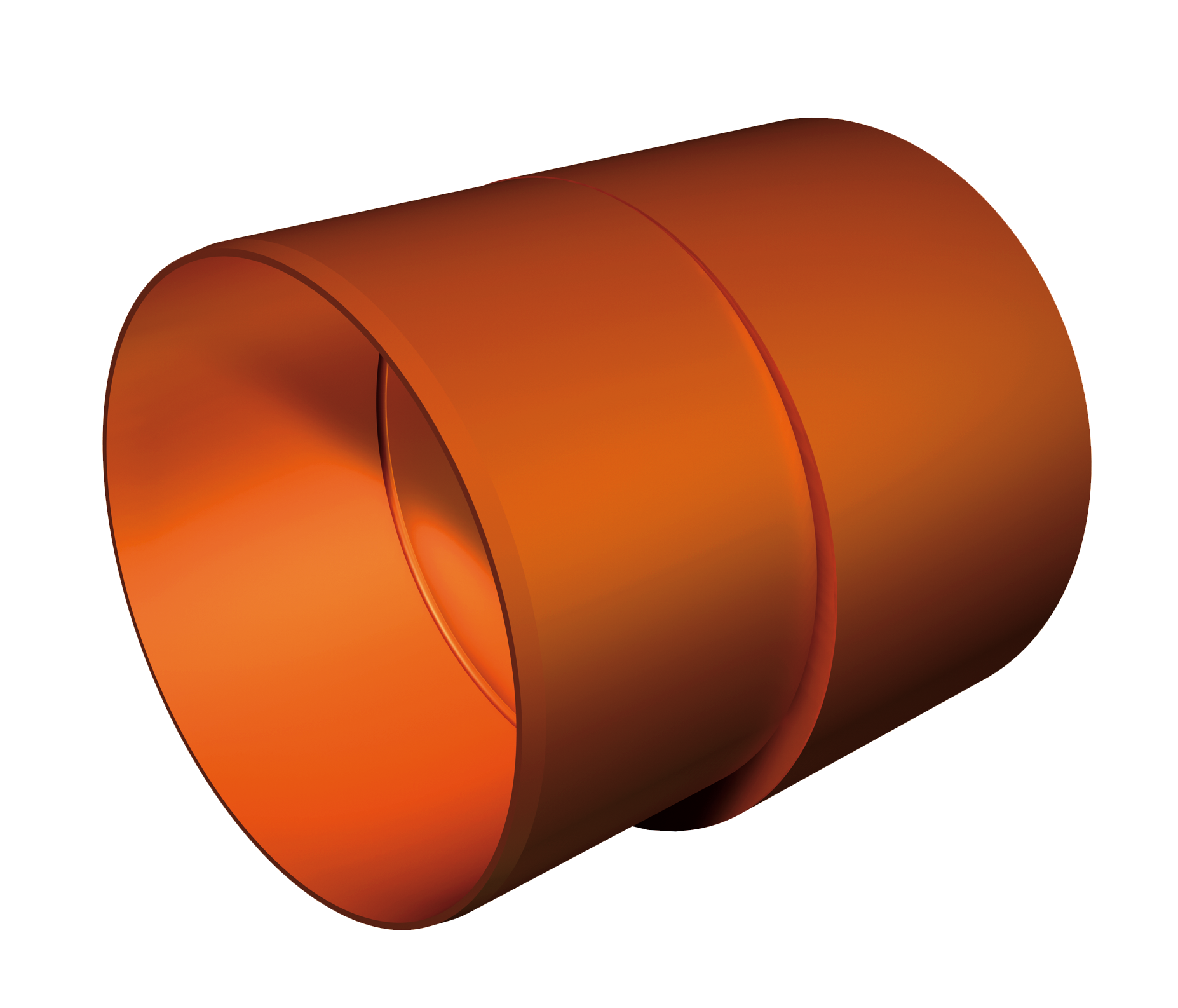

Connections DN/OD 160, 200, 250, 315, 400 mm

Molded ring type manhole DN 1000 [mm] with stationary or self leveling type D400 class cast iron cover and integrated steps.

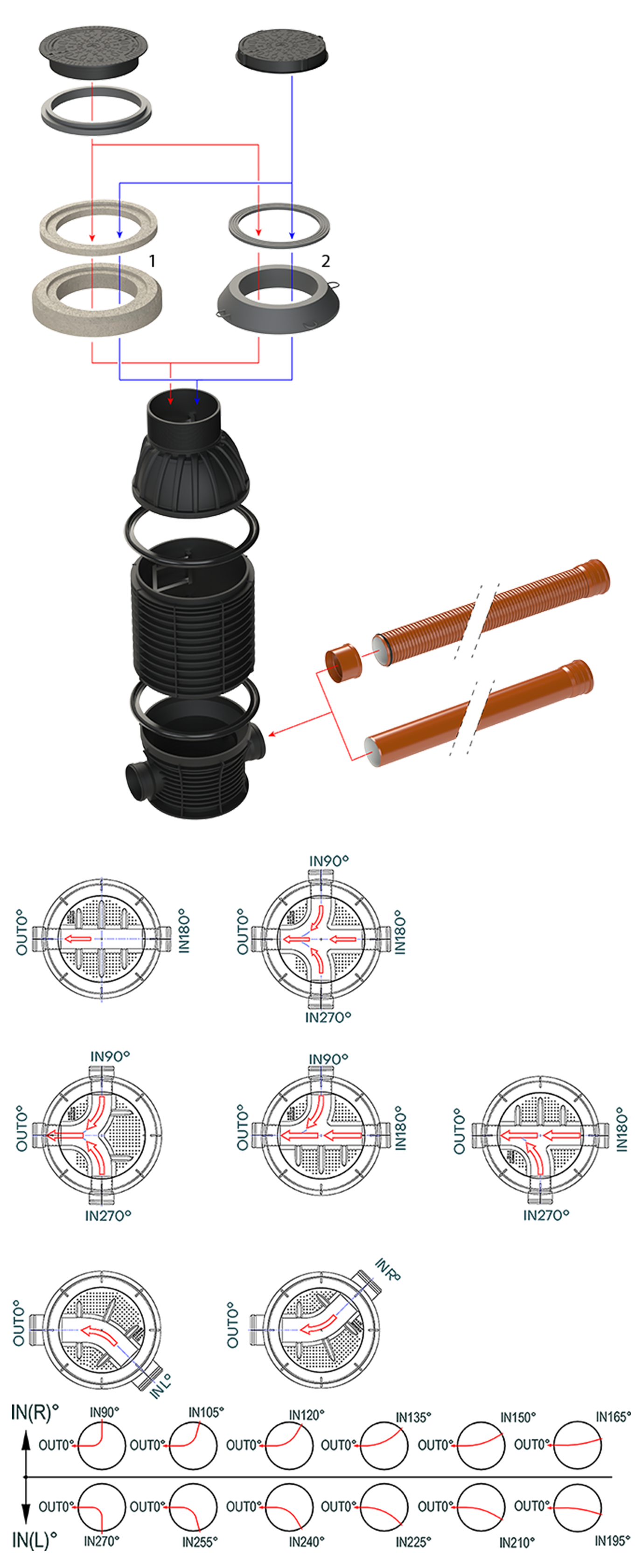

- Base configuration:

- 1B 180°

- 3BL 90°, 180°, 270°

- 2BT 90°, 270°

- 2BL 180°, 270° or 90°, 180°

- 1BB 90°.. 270°

- Connection DN/OD 110 .. 400 [mm]

- Access shaft DN 625 [mm]

- Cover: D400 class, RAL GZ-692

-

Advantages

Very long service life (>100 years)

Flexibile for movements in soil (no cracking of the manhole)

100% watertight

Integrated polypropylene (PP) steps

Flexible connection to manhole +/- 3.75°

Manhole is manufactured from 100% first-use PP

-

Recommended application

Yards of multi-storey dwellings

Parking places and vehicle storage areas

Pavements, pedestrian and bicycle paths

Stadiums and sport complexes

Road construction (with and without transport load)

-

Manhole components

1 to be used in cases of paving stone, gravel or green space.

2 to be used in asphalt concrete pavement.

-

Technical information

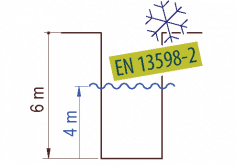

Installation depth

Minimum instalation depth: 1.25 m

Maximum installation depth is up to 6.0 m, if the ground water level is 2.0 m from the surface. If the ground water level is 0.0 m from the surface, the maximum installation depth is 5.0 m, according to the requirements of EN 13598-2 standard

The spout of the manhole

The spout of the manhole base is molten in white colour to facilitate CCTV control. The spout of the manhole is made with 100% filling and 0.5% fall. Racks along the spout are made of with anti-slip profiled surface with fall in direction of the spout.

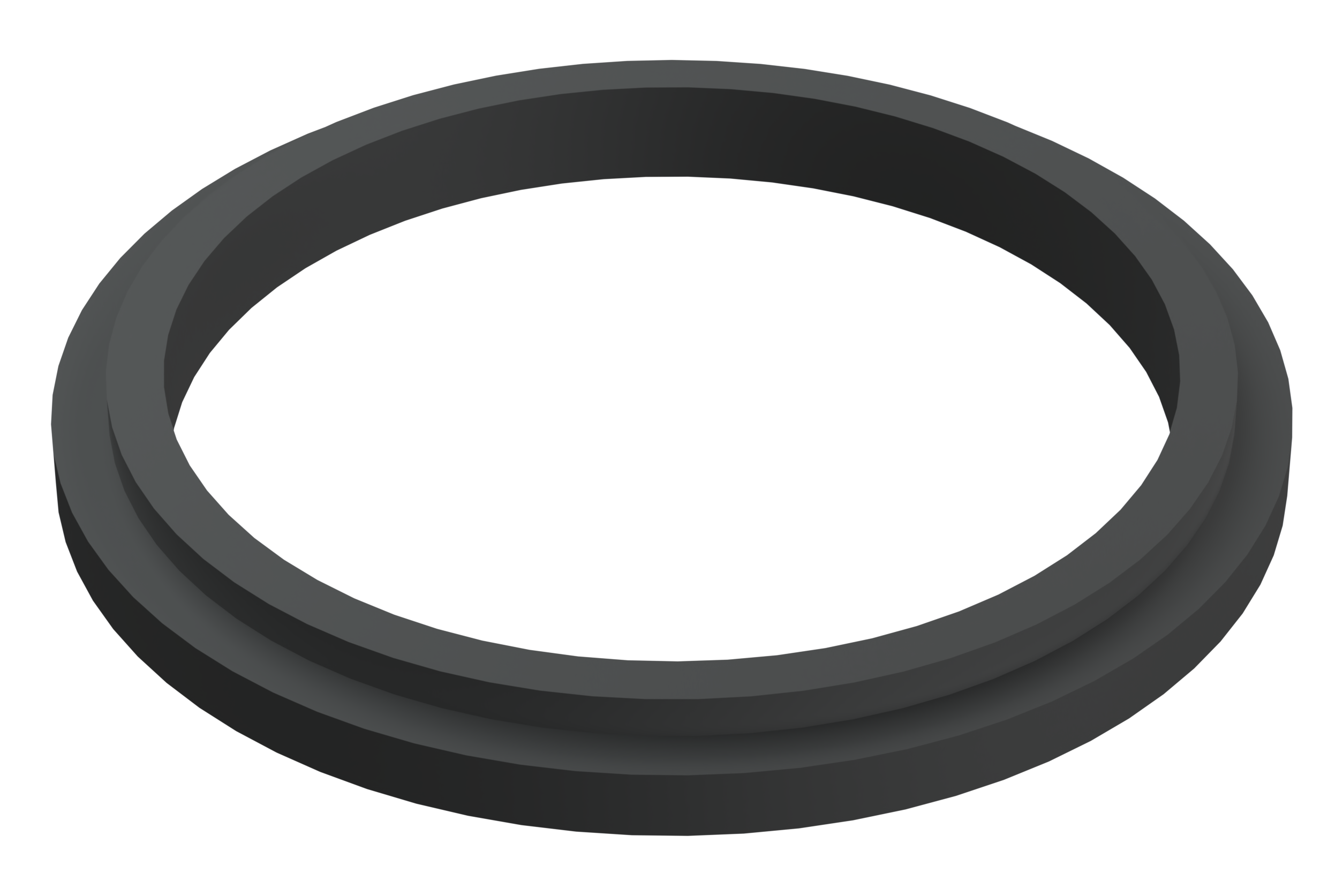

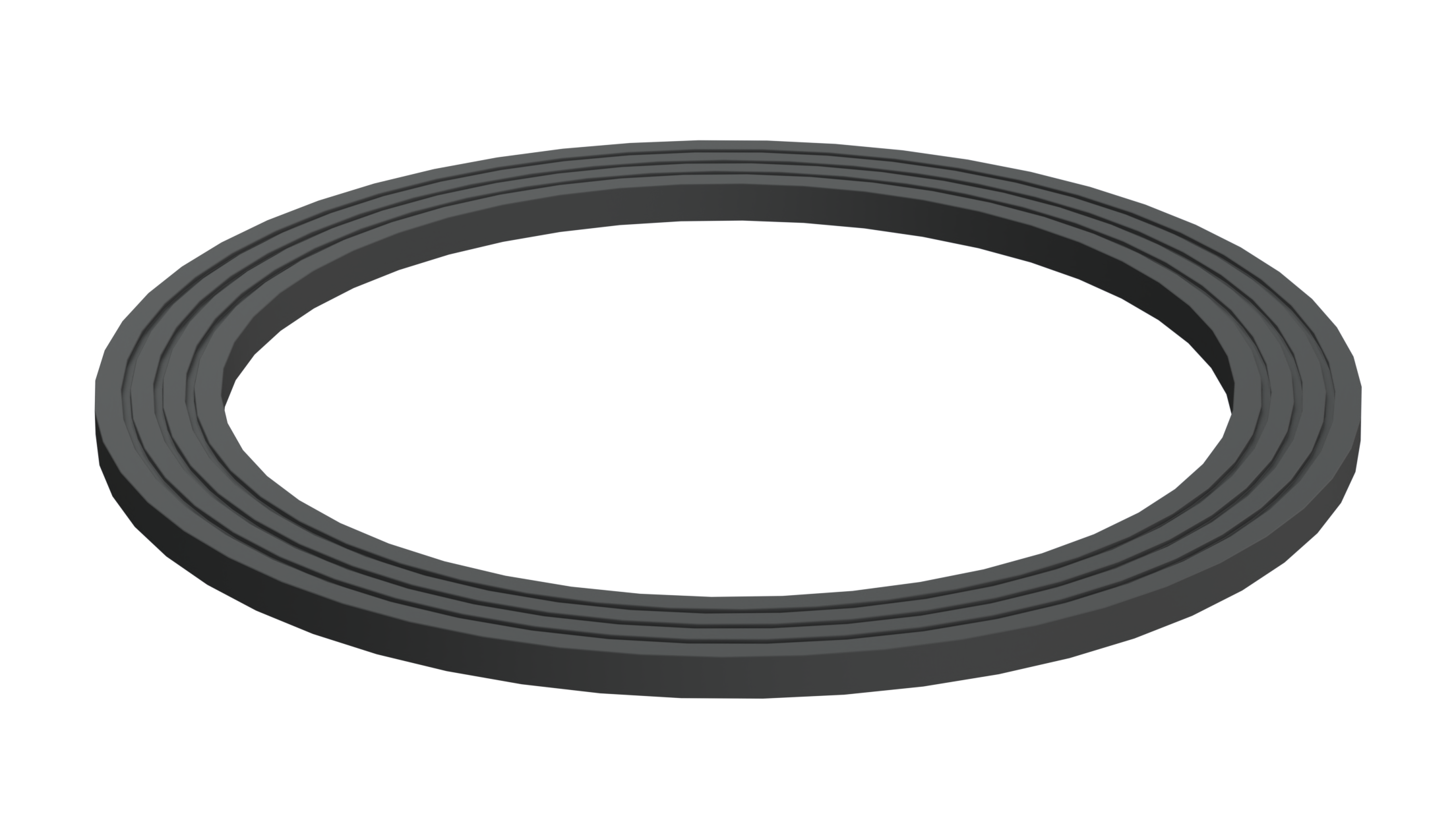

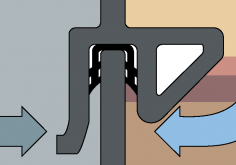

Sealing rings

To ensure the water-tightness of the manhole, the connecting elements are connected with rubber sealing rings DN 1000 [mm], corresponding to the requirements of EN 681-1 and EN 1277 standards. The rubber sealing rings ensure the maximum pressure of 0.5 [bar].

Polypropylene steps

Especially enduring glass fibre reinforced polypropylene material steps in the manhole are constructed according to the requirements of EN 13101 or EN 14396 standards or to requirements of Latvian or European safety norms (related to human work safety) stating that the first steps in manhole must be 30 cm from the ground/road surface, but the distance between the next steps may be 25 cm. Steps are anti-slip and corrosion-resistant, in white colour.

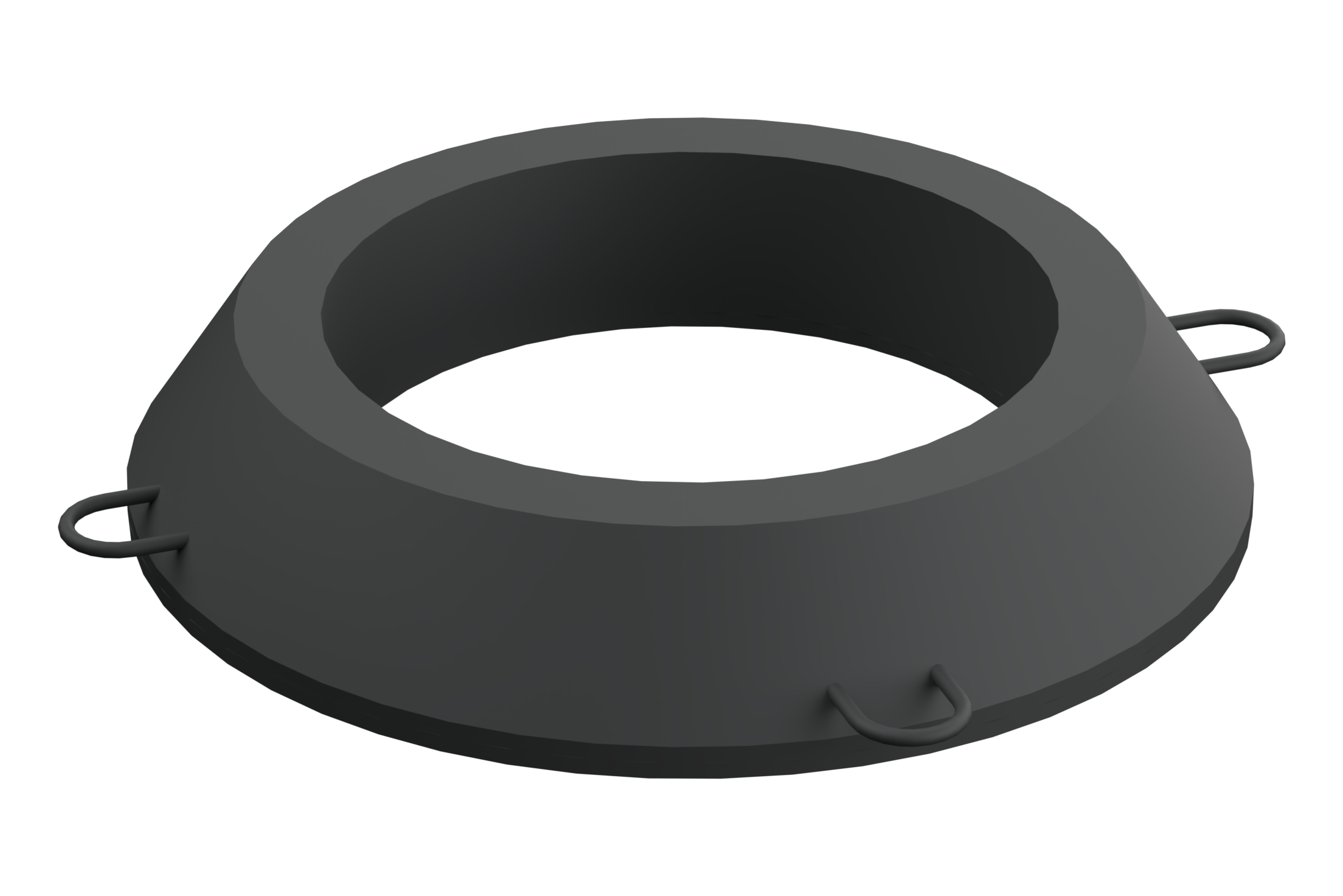

Eccentric cone

Manhole neck access hole DN 625 mm, as well as the steps, which have been built-in according to the requirements of EN 476 and EN 13598-2 standards, allows to enter the manhole during operation phase in case such need arises for the service personnel. Manhole cone can be shortened by 25 cm if necessary.

Manhole covers

Self-leveling type cast iron frame and cover, DN 700 [mm], installation class D400 (40t) corresponds to the requirements of EN 124-2 and RAL GZ-692 standard.

Stationary type cast iron frame and cover, DN 600/746 [mm], installation class D400 (40t) corresponds to the requirements of EN 124-2 and RAL GZ-692 standard.

Polymer ring adapter for self-leveling cover DN 710/870 [mm], durability tests are carried out corresponding to the requirements of EN 124 standard.

Polymer height adjustment ring DN 700/875 [mm], durability tests are carried out corresponding to the requirements of EN 124 standard.

Polymer support ring DN 680/1050 [mm], durability tests are carried out corresponding to the requirements of EN 124 standard.

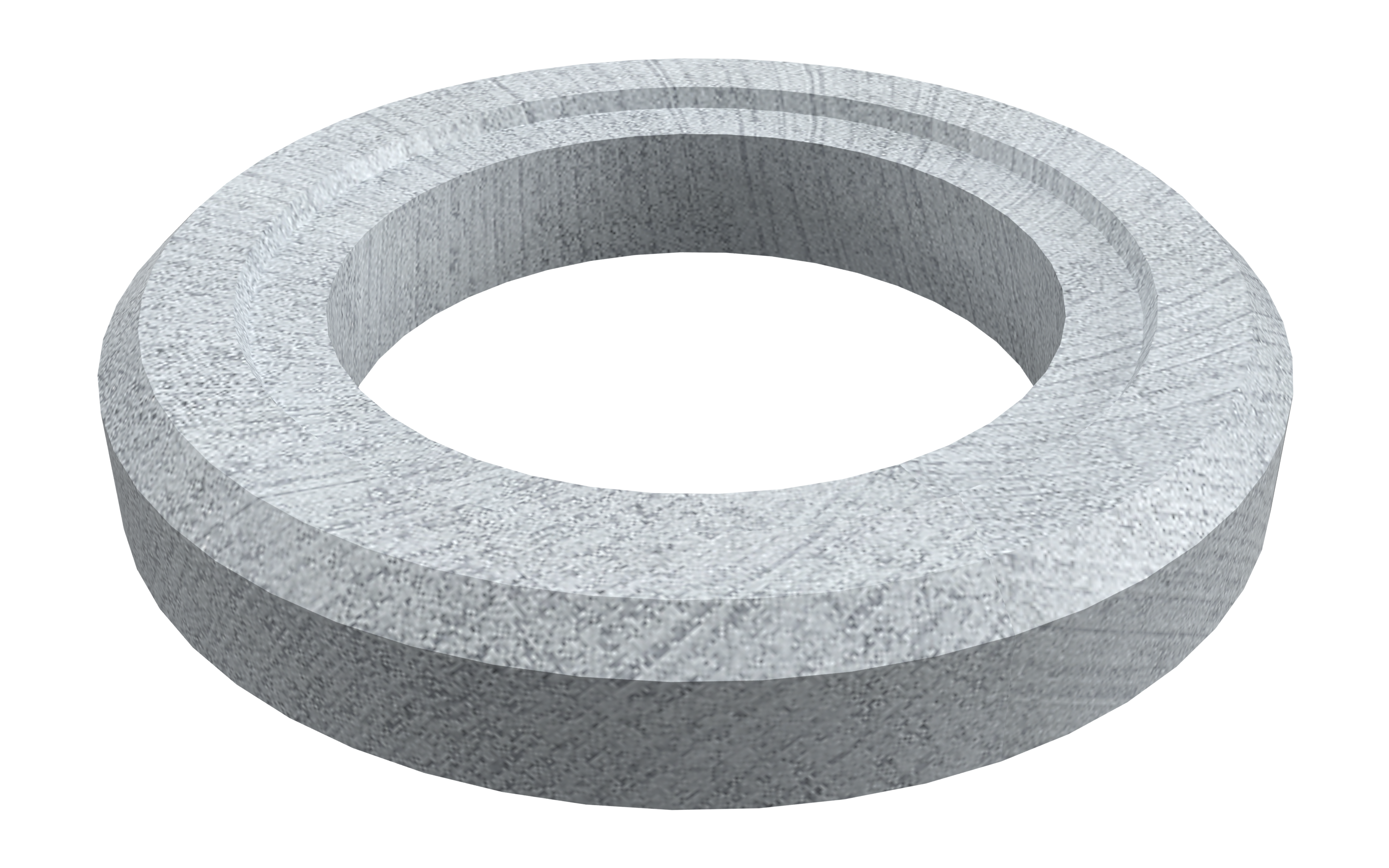

Reinforced concrete height adjustmet ring, DN 665/1000 [mm], corresponds to the requirements of EN 206, EN 1917 and EN 1917/AC standard.

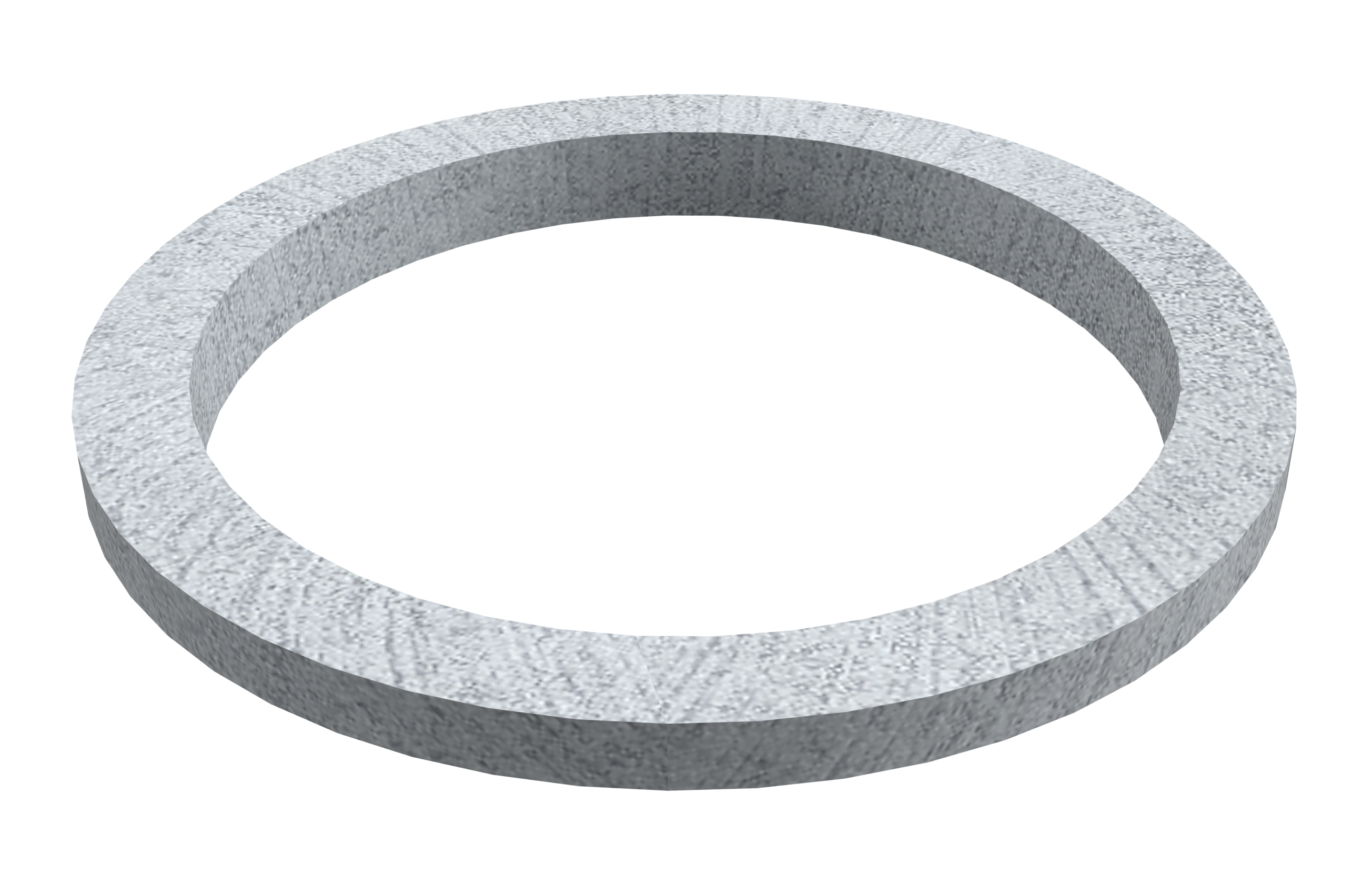

Reinforced concrete support ring, DN 665/1060 [mm], corresponds to the requirements of EN 206, EN 1917 and EN 1917/AC standard.

-

Drawings