Energy-absorbing chambers ECC 1000.625

Utility wastewater and stormwater energy-absorbing chamber

Outlet: DN/OD 200, 250, 315, 400 mm; Inlet: DN/OD 160-355 mm

Energy-absorbing chambers DN 1000 for utility wastewater and stormwater systems. Made from polyethylene (PE) material with D400 class self leveling or stationary type cover.

- Connections:

- Inlet DN/OD 160 .. 355 [mm]

- Outlet DN/OD 200 .. 400 [mm]

- Cover: D400 class (40t), RAL GZ-692

- Access diameter 625 [mm]

-

Advantages

No stagnant water in the chamber

Resistant to aggressive environment, no corrosion

Long service life (>50 years)

Flexibile for movements in soil (no cracking of the manhole)

Water-tightness > 0.5 bar, watertight materials

The diameter of access hole allows convenient and quick maintenance of sewerage networks

-

Recommended application

Intended for utility sewerage and rainwater pressure systems:

- SDR17, PE80 class EN 12201-2+A1 pipes with nominal pressure class PN8 [bar];

- SDR17, PE100 class EN 12201-2+A1 pipes with nominal pressure class PN10 [bar];

- SDR17, PE100-RC class EN 12201-2+A1, PAS 1075 pipe types- 1, 2, 3 with nominal pressure class PN10 bar.

Chamber installation according to: EN 1610, CEN/TR 1046

Construction work related to chamber cover and upper part of chamber shall be performed in accordance with road or territory manager’s issued technical regulations and sewer system operator (water management service provider’s) requirements.

-

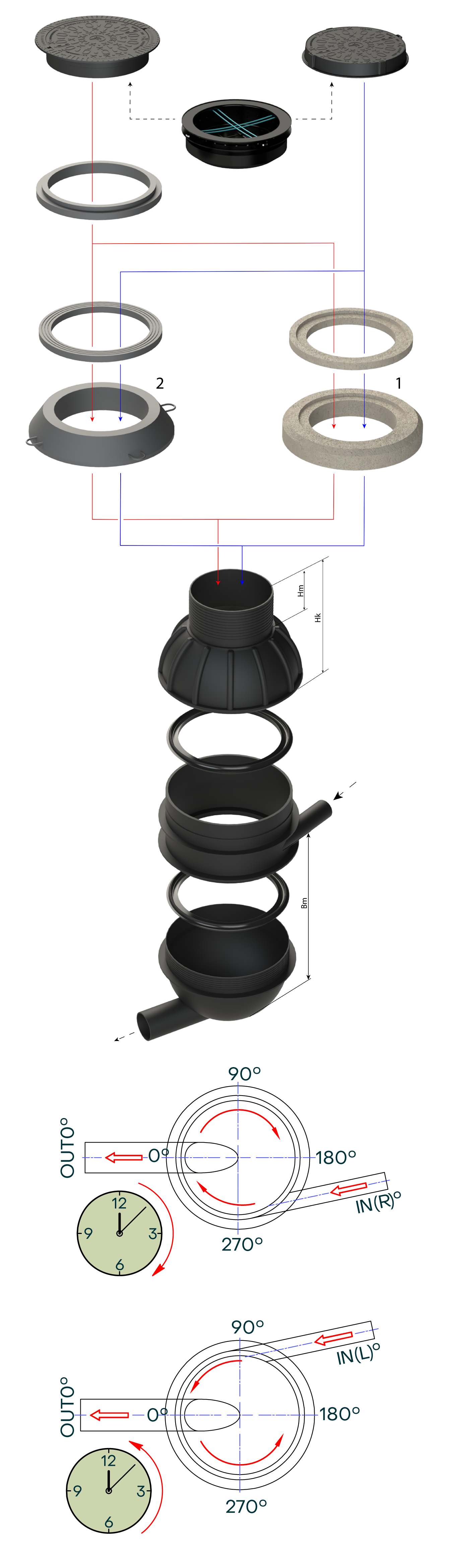

Chamber components

- OUT 0° DN 200 - IN R/L° DN 160

- OUT 0° DN 250 - IN R/L° DN 180, 200

- OUT 0° DN 315 - IN R/L° DN 225, 250, 280

- OUT 0° DN 400 - IN R/L° DN 315, 355

Note: On demand it is possible to manufacture inlet “IN(R/L)°” with flange connection

1 to be used in cases of paving stone, gravel or green space.

2 to be used in asphalt concrete pavement.

-

Technical information

Installation depth:

- Minimum instalation depth: 1,20 [m]

- Maximum installation depth is up to 6.0 [m], if the ground water level is 2.0 [m] from the surface. If the ground water level is 0.0 [m] from the surface, the maximum installation depth is 5.0 [m], according to the requirements of EN 13598-2 standard

Chamber cover:

- Stationary type cast iron frame and cover, DN 600/746 [mm], installation class D400 (40t) corresponds to the requirements of EN 124-2 and RAL GZ-692 standard

- Self-leveling type cast iron frame and cover, DN 700 [mm], installation class D400 (40t) corresponds to the requirements of EN 124-2 and RAL GZ-692 standard

- Polymer ring adapter for self-leveling cover DN 710/870 [mm], durability tests are carried out corresponding to the requirements of EN 124 standard.

- Polymer height adjustment ring DN 700/875 [mm], durability tests are carried out corresponding to the requirements of EN 124 standard.

- Polymer support ring DN 680/1050 [mm], durability tests are carried out corresponding to the requirements of EN 124 standard.

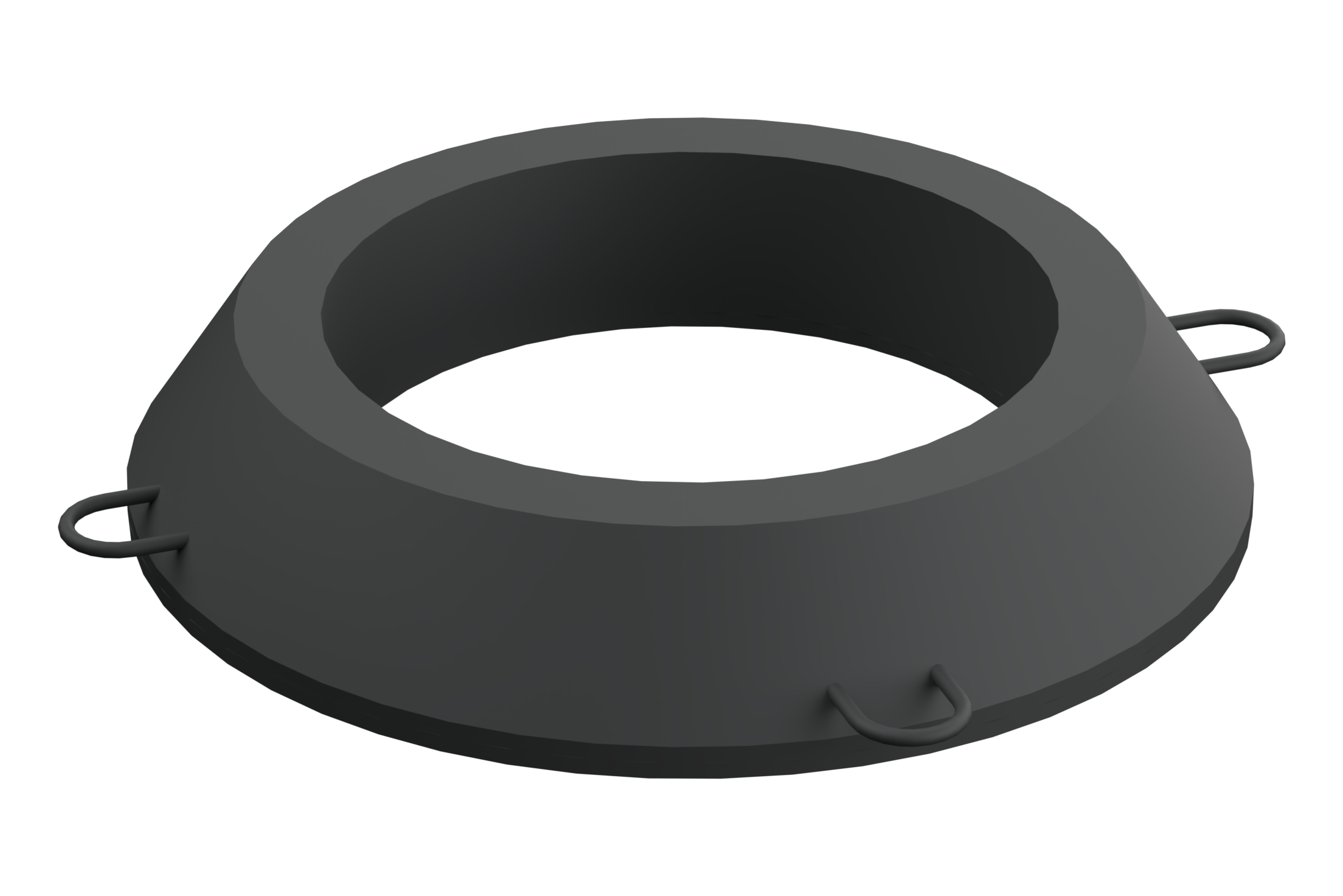

- Reinforced concrete height adjustmet ring, DN 665/1000 [mm], corresponds to the requirements of EN 206, EN 1917 and EN 1917/AC standard

- Reinforced concrete support ring, DN 665/1060 [mm], corresponds to the requirements of EN 206, EN 1917 and EN 1917/AC standard

Chamber shaft and base:

- Polyethylene (PE) eccentric cone, DN 1000/625, h=750/1000 [mm], corresponds to the requirements of EN 14802

- Polyethylene (PE) chamber shaft, DN 1000, h=500/1000 [mm], corresponds to the requirements of EN 14802

- Polyethylene (PE) chamber base, DN 1000, h=700/1000 [mm], corresponds to the requirements of EN 13598-2, EN 476

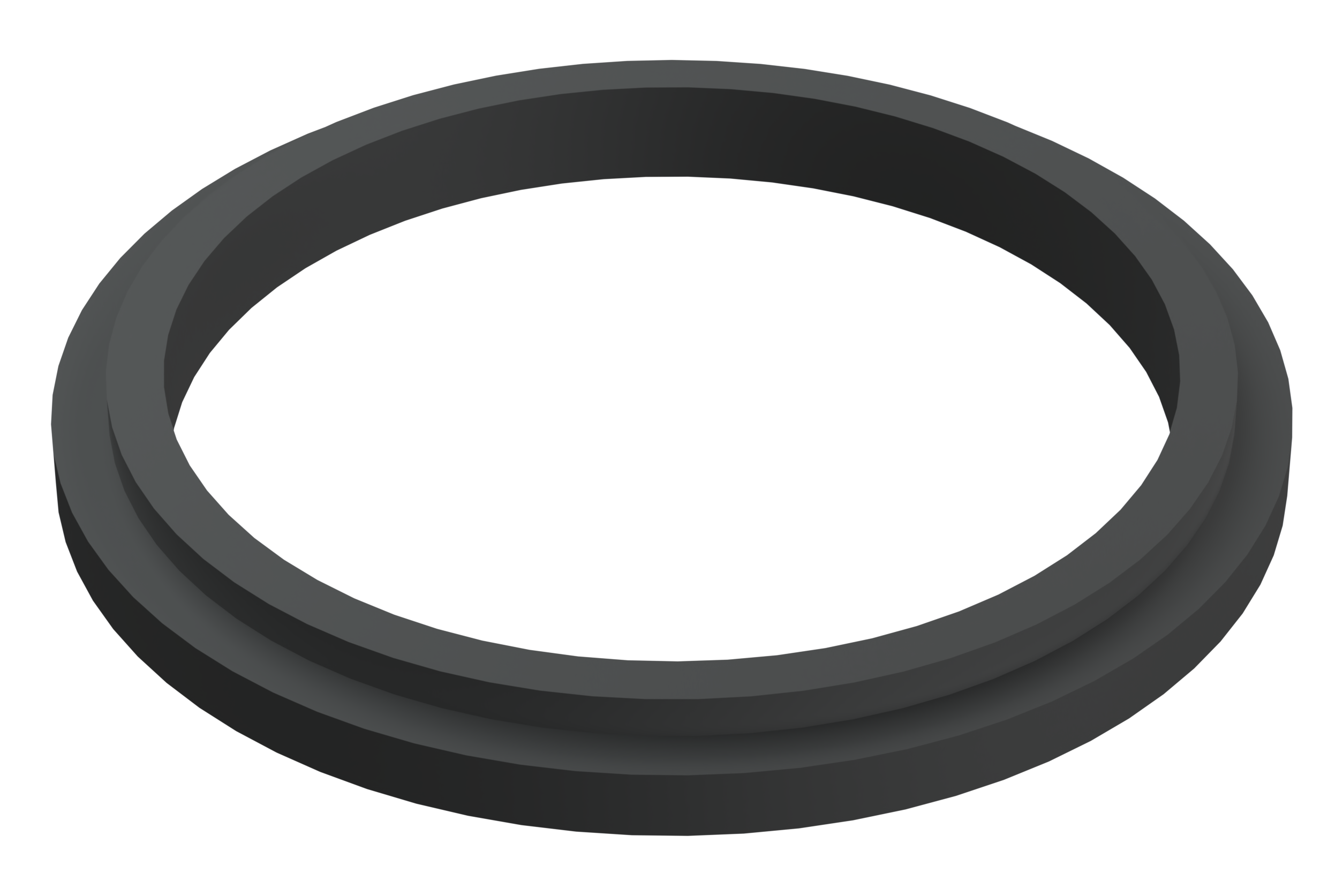

- To ensure the water-tightness of the chamber, the connecting elements are connected with rubber sealing rings DN 1000 [mm] corresponding to the requirements of EN 681-1 and EN 1277 standards. The chamber must ensure the maximum pressure of 0.5 [bar]

According to the requirements of EN 681-1 and EN 1277 standards, rubber sealing rings of chambers have to ensure water-tightness of connections at water pressure of 0.5 [bar]

-

Drawings

.png)