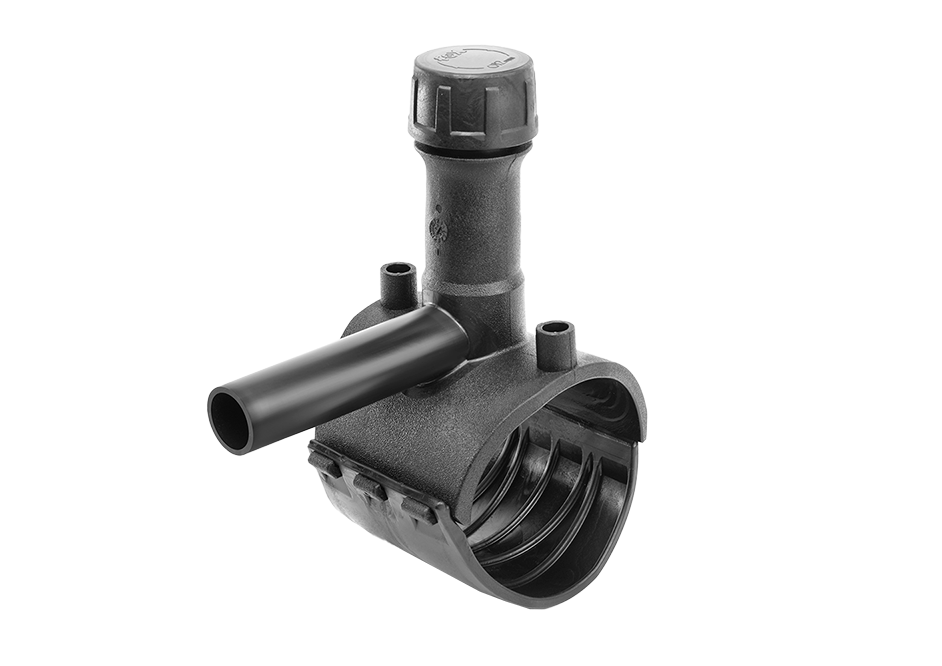

Electrofusion tapping T-piece

Electrofusion fitting PE100-RC

DN/OD 40-315 mm

![]()

Branch saddle tapping T-pieces is made of high-density polyethylene PE100-RC type material. The construction contains one or several integrated heating elements, which ensure the transformation of electricity into the heat of fusion.

- Pressure class PN16 (water) and PN10 (gas)

- SDR class: 11

- MRS: 10 [MPa]

-

Advantages

- PE100-RC material is resistant to the long-term expansion of cracks, scratching, and point-type loads. Point-type loads are especially common during the assembly of the pipelines using trenchless installation methods (for instance, as a result of friction against the stones that are present in the soil). In the case of a point-type load, tension, and plastic deformations are produced in the material, which may cause cracks in the internal surface.

- The result of applying electrofusion fittings is a solid and safe joint of pipe and any other elements belonging to the pipeline system. The electrofusion joint features excellent pressure resistance and tightness.

-

Recommended application

Tapping T-pieces are used in installations distributing gas and water.

-

Installation

-

Technical information

- Material: Polyethylene PE100-RC

- SDR class: 11

- MRS: 10 [MPa]

- Work pressure water systems: 16 [bar]

- Work pressure gas systems: 10 [bar]

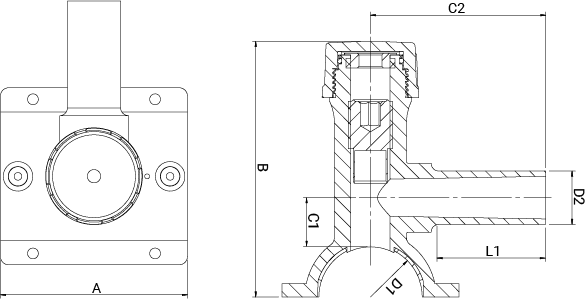

Product dimensions

D1 [mm] D2 [mm] A [mm] B [mm] L1 [mm] C1 [mm] C2 [mm] Assembly¹ Type² Weight [kg] 40 20 127 105 70 13 92 c v1 0.32 40 25 127 105 70 13 92 c v1 0.32 40 32 127 105 70 13 92 c v1 0.33 50 20 115 157 66 30 106 c v1 0.52 50 25 114 157 65 30 106 c v1 0.54 50 32 114 157 65 30 106 c v1 0.55 50 40 114 156 82 30 104 c v1 0.56 63 20 115 158 65 30 106 c v1 0.49 63 25 115 157 65 30 106 c v1 0.50 63 32 115 157 65 30 106 c v1 0.50 63 40 115 157 83 30 105 c v1 0.52 63 50 127 227 106 89 137 c v2 0.75 63

63 126 227 111 75 139 c v2 0.94 75 20 115 157 66 30 105 b v1 0.58 75 25 115 157 64 33 105 b v1 0.52 75 32 115 157 666 30 105 b v1 0.52 75 40 115 157 83 30 105 b v1 0.49 75 50 127 227 108 88 138 c v2 0.72 75 63 127 226 98 90 136 c v2 0.98 90 20 128 242 77 88 138 c v2 1.03 90 25 128 242 77 87 138 c v2 0.83 90 32 128 242 85 87 138 c v2 1.00 90 40 128 240 107 87 138 c v2 1.02 90 50 128 240 107 87 138 c v2 1.05 90 63 128 242 98 87 137 c v2 0.90 110 20 128 182 69 30 105 c v1 0.70 110 25 128 181 70 30 106 c v1 0.73 110 32 128 181 65 30 105 c v1 0.72 110 40 128 181 82 30 104 c v1 0.70 110 50 129 251 105 87 137 c v2 1.18 110 63 128 252 98 88 137 c v2 1.04 125 20 128 182 65 30 105 c v1 0.79 125 25 128 182 69 30 105 c v1 0.71 125 32 128 181 65 30 105 c v1 0.71 125 40 128 181 83 28 104 c v1 0.71 125 50 129 249 109 88 137 c v2 0.97 125 63 128 247 98 88 136 c v2 1.03 140 20 128 246 78 88 138 b v2 0.99 140 25 129 247 85 88 138 b v2 0.81 140 32 128 246 85 88 138 b v2 0.97 140 40 128 246 85 88 138 b v2 1.00 140 50 128 248 106 88 137 b v2 1.03 140 63 129 248 98 88 137 b v2 0.91 160 20 189 265 78 83 138 c v2 1.50 160 25 189 265 85 82 138 c v2 1.31 160 32 189 265 85 82 138 c v2 1.47 160 40 189 266 106 83 138 c v2 1.33 160 50 189 265 106 82 137 c v2 1.37 160 63 189 264 98 82 136 c v2 1.63 180 20 190 264 85 82 138 c v2 1.53 180 25 190 267 85 82 138 c v2 1.55 180 32 189 265 85 82 138 c v2 1.53 180 40 189 261 107 82 138 c v2 1.54 180 50 189 265 107 82 137 c v2 1.61 180 63 189 265 98 82 136 c v2 1.46 200 20 168 247 85 88 138 b v2 1.23 200 25 168 247 85 88 138 b v2 1.12 200 32 168 247 85 88 138 b v2 1.14 200 40 170 247 107 88 138 b v2 1.34 200 50 169 245 106 88 137 b v2 1.17 200 63 170 247 98 88 136 b v2 1.45 225 20 170 248 85 88 139 b v2 1.35 225 25 170 248 85 88 139 b v2 1.13 225 32 170 247 85 88 138 b v2 1.35 225 40 170 245 111 90 140 b v2 1.35 225 50 169 246 107 88 137 b v2 1.35 225 63 169 244 98 88 136 b v2 1.47 250 20 169 245 85 87 138 b v2 1.38 250 25 169 245 85 87 138 b v2 1.19 250 32 169 245 85 87 138 b v2 1.35 250 40 169 245 106 88 138 b v2 1.38 250 50 168 245 109 88 137 b v2 1.42 250 63 169 245 98 88 136 b v2 1.50 280 20 169 244 84 86 138 b v2 1.33 280 25 169 244 84 88 138 b v2 1.33 280 32 169 244 84 86 138 b v2 1.41 280 40 169 244 98 86 136 b v2 1.42 280 50 169 244 98 88 136 b v2 1.42 280 63 169 244 98 88 136 b v2 1.52 315 20 170 247 86 87 140 b v2 1.37 315 25 170 247 86 87 140 b v2 1.37 315 32 170 247 86 87 140 b v2 1.38 315 40 169 244 98 88 136 b v2 1.42 315 50 169 244 98 88 136 b v2 1.49 315 63 169 244 98 88 136 b v2 1.54 Assembly¹ b - belt, c - PE detail

Type²: Wrench - Accessories -

Certificates

FOX Electrofusion Fittings DN 20-63 Certificate ENG

DVGW-type examination certificate (DVGW cert)

Download

FOX Electrofusion Fittings DN 75-225 Certificate ENG

DVGW-type examination certificate (DVGW cert)

Download

FOX Electrofusion Fittings DN 250-630 Certificate ENG

DVGW-type examination certificate (DVGW cert)

Download