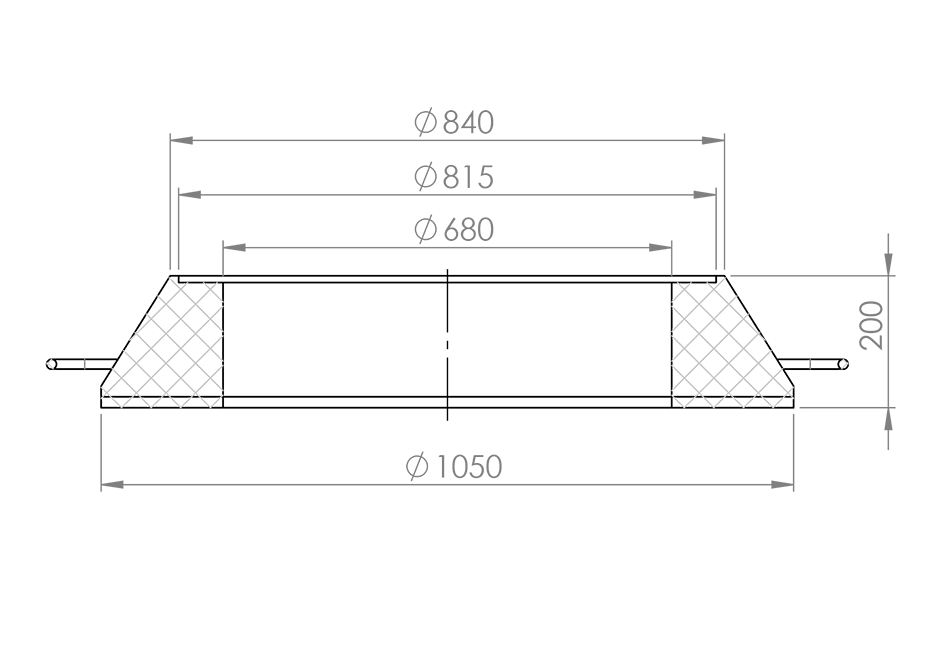

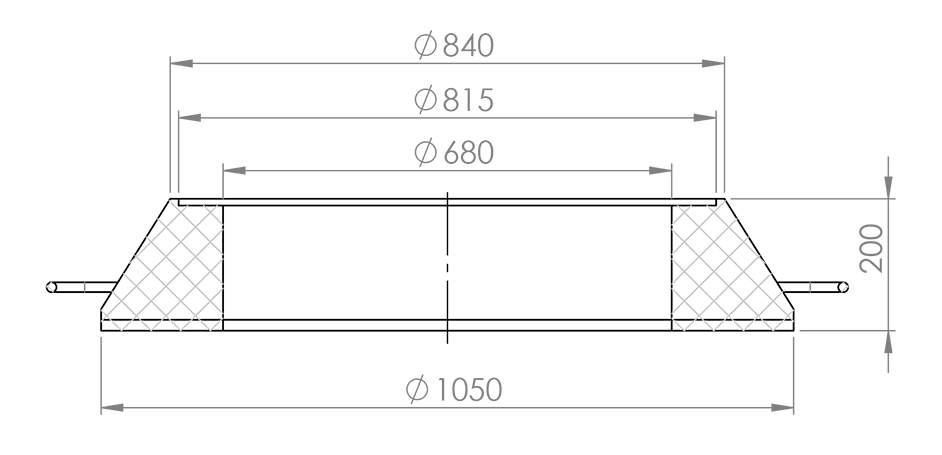

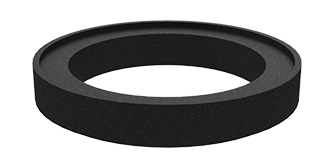

T3/680

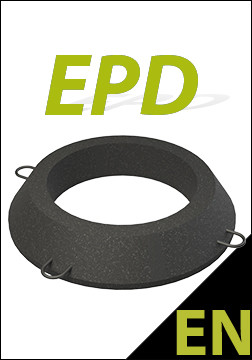

Support ring

DN 680/1050 mm

Polymer support ring for construction of self-leveling and stationary type covers.

-

Advantages

-

Construction

- Chamber cover finial elements made from polymer are suitable for:

- all the EVOPIPES chambers;

- reconstruction of chamber covers of reinforced concrete chambers.

When assembling polymer chamber cover elements, one above the other, use silicone mastic, Ø 3-5 mm in two strips, on the surface of the polymer element!

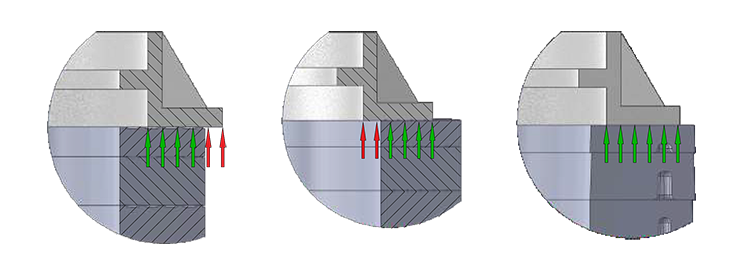

During the assembly process the following remarks must be taken into account:

- Do not assemble the polymer surface finial elements on an unprepared ground, uneven, unlevelled, and unrepaired surface supporting the adjustment elements and in case of relief elements - on an uncompacted ground or substructure;

- Do not use cement-based mortar between polymer elements in the finial structure and between polymer and cast-iron elements of chamber finial;

- Do not make high adjustment based only on compensation rings with small dimensions (e.g. 21 cm adjustment made using 10 pcs of 15 mm rings and 2 pcs of 3 cm rings), as the possibility of height problem occurring during the operation increases the finial costs without any justification;

- Make sure that that frame of chamber cover is perfectly placed on the polymer elements.

- Chamber cover finial elements made from polymer are suitable for:

-

Technical information

- Compressive strength

Class D400 (>500 kN)

- Weight

76,7 kg

- Specific weight

1,45 kg/dm3

- Material

Composition of termoplastic polymers (PVC, PE and PEX)

- Hardness

46 sec. Shor'e D

- Absorption capacity

<0,02%

- Mechanical loss factor

ni<=0,33

- Resistance to freezing in water

F150(-2%)

- Frost resistance in 2% NaCl

F50(-2%)

- Heat resistance

from-30 to +60°C

- Chemical resistance

Highly resistant to acids, alkaline substances, salts, fats, oils and solvents

- Thermal resistance during assembly (in contact with asphalt)

Short, about 2 hours to 170°C