Flange with stub end

Butt-fusion fitting PE100-RC

DN 32-630 mm

![]()

Flange with stub end is used to form a transition from a PE pipe to a cast-iron pipe (together with a Flange with PP coating). Made of high-density polyethylene PE100-RC type material.

- SDR: 17 and 11

-

Advantages

- PE100-RC material is resistant to the long-term expansion of cracks, scratching, and point-type loads. Point-type loads are especially common during the assembly of the pipelines using trenchless installation methods (for instance, as a result of friction against the stones that are present in the soil). In the case of a point-type load, tension, and plastic deformations are produced in the material, which may cause cracks in the internal surface.

-

Recommended application

Flange with stub end is used in installations distributing gas and water.

-

Installation

The butt fusion involves heating the ends of two pipe/fitting components (from PE100-RC material) which are to be joined until a molten state is attained on each contact surface. The two surfaces are then brought together under controlled pressure for a specific cooling time and a homogeneous fusion joint is formed.

The resultant joint is fully resistant to end loads and has comparable performance under pressure to the pipe itself.

-

Technical information

- Material: Polyethylene PE100-RC

- Work pressure water systems: 16 [bar] for SDR11 fittings; 10 [bar] for SDR17 fittings

- Work pressure gas systems: 10 [bar] for SDR11 fittings; 5 [bar] for SDR17 fittings

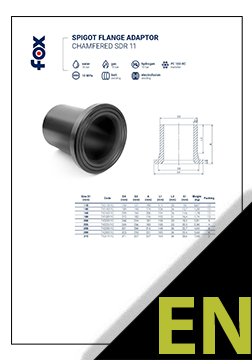

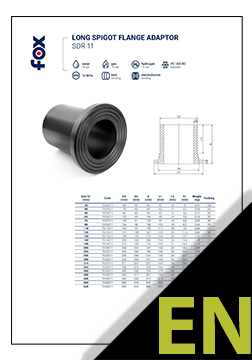

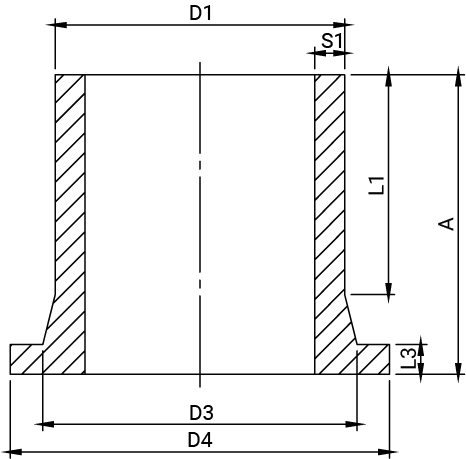

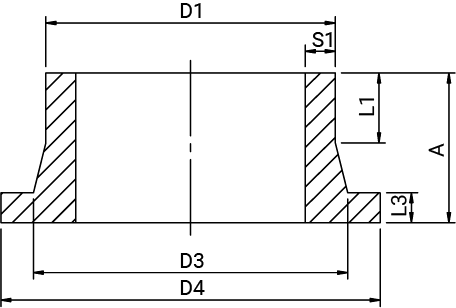

Product dimensions STANDARD SPIGOT

SDR17

D1 [mm] D4 [mm] D3 [mm] A [mm] L1 [mm] L3 [mm] S1 [mm] Weight [kg] 63 101 72 104 67 14 3,8 0,15 75 120 84 126 94 16 4,5 0,25 90 136 100 140 106 17 5,4 0,36 110 154 115 155 112 20 6,6 0,54 125 156 129 171 125 25 7,4 0,65 140 188 156 174 125 25 8,3 0,98 160 209 166 207 157 25 9,5 1,44 180 211 185 178 153 21 10,7 1,24 200 265 220 187 132 33 11,9 2,20 225 267 235 190 131 33 13,4 2,27 250 317 273 217 137 36 14,8 3,73 280 318 284 228 143 36 16,6 3,94 315 368 332 238 156 36 18,7 5,25 355 430 376 233 164 30 21,1 6,25 400 480 430 246 179 33 23,7 8,13 450 585 517 287 195 46 26,7 13,83 500 585 533 300 212 46 29,7 15,21 560 685 618 330 235 50 33,2 17,18 630 685 645 340 255 50 37,4 24,86 STANDARD SPIGOT

SDR11

D1 [mm] D4 [mm] D3 [mm] A [mm] L1 [mm] L3 [mm] S1 [mm] Weight [kg] 32 68 40 86 62 10 3 0,05 40 78 50 89 62 11 3,7 0,08 50 88 60 90 62 12 4,6 0,12 63 102 69 104 68 14 5,8 0,18 75 120 81 123 91 16 6,8 0,30 90 136 98 138 105 18 8,2 0,44 110 154 121 155 111 20 10 0,66 125 157 128 167 122 25 11,4 0,86 140 188 156 174 125 25 12,7 1,27 160 209 165 206 154 26 14,6 1,78 180 212 182 176 152 21 16,4 1,74 200 266 217 187 133 33 18,2 2,81 225 267 231 185 130 33 20,5 2,95 250 317 270 216 140 36 22,7 4,71 280 316 281 231 185 36 25,4 5,26 315 368 322 237 165 36 28,6 7,23 355 430 376 243 164 40 32,3 8,90 400 480 430 259 179 46 36,4 11,92 450 585 517 301 195 60 40,9 19,93 500 585 533 314 212 60 45,5 21,99 560 685 618 345 235 72 50,9 33,80 630 685 645 360 255 65 57,3 37,50 SHORT SPIGOT

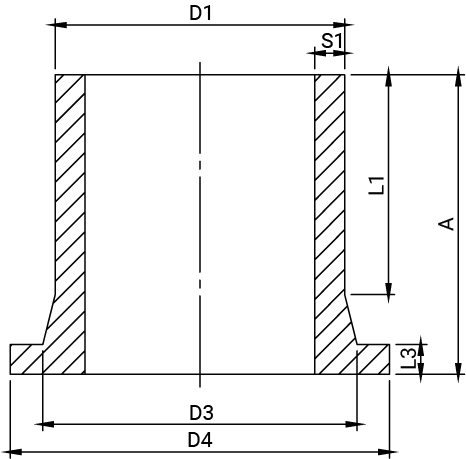

SDR17

D1 [mm] D4 [mm] D3 [mm] A [mm] L1 [mm] L3 [mm] S1 [mm] Weight [kg] 355 430 376 120 65 30 21,1 3,58 400 480 430 120 63 33 23,7 4,43 450 585 517 120 50 60 26,7 9,95 500 585 533 120 50 46 29,7 7,26 560 685 618 130 40 50 33,2 10,90 630 685 645 120 50 50 37,4 10,23 710 800 740 140 50 60 42,1 15,47 800 900 833 140 50 60 47,4 20,12 900 1000 937 155 50 65 53,3 26,27 1000 1112 1040 170 50 70 59,3 36,28 SHORT SPIGOT

SDR11

D1 [mm] D4 [mm] D3 [mm] A [mm] L1 [mm] L3 [mm] S1 [mm] Weight [kg] 355 430 376 120 55 40 32,3 4,93 400 480 430 120 50 46 36,4 6,43 450 585 517 140 45 60 40,9 11,93 500 585 533 140 50 60 45,5 11,25 560 685 618 165 41 72 50,9 17,70 630 685 645 140 50 65 57,3 15,95 710 800 740 145 50 65 64,5 22,44 -

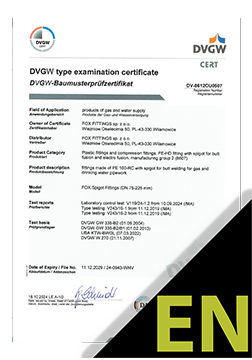

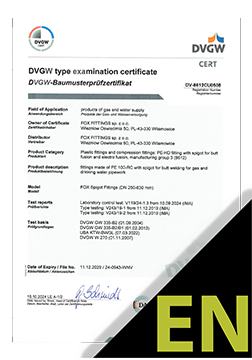

Certificates