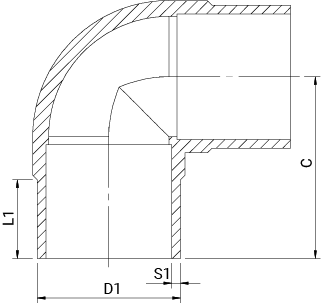

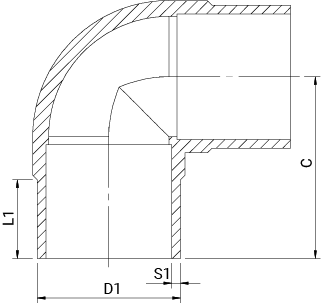

Spigot elbow 90°

Butt-fusion fitting PE100-RC

DN/OD 20-315 mm

![]()

Spigot Elbow 90° made of high-density polyethylene PE100-RC type material.

- Pressure class PN16 and PN10

-

Advantages

- PE100-RC material is resistant to the long-term expansion of cracks, scratching, and point-type loads. Point-type loads are especially common during the assembly of the pipelines using trenchless installation methods (for instance, as a result of friction against the stones that are present in the soil). In the case of a point-type load, tension, and plastic deformations are produced in the material, which may cause cracks in the internal surface.

-

Recommended application

Spigot elbows are used in installations distributing gas and water.

-

Installation

The butt fusion involves heating the ends of two pipe/fitting components (from PE100-RC material) which are to be joined until a molten state is attained on each contact surface. The two surfaces are then brought together under controlled pressure for a specific cooling time and a homogeneous fusion joint is formed.

The resultant joint is fully resistant to end loads and has comparable performance under pressure to the pipe itself.

-

Technical information

- Material: Polyethylene PE100-RC

- Work pressure water systems: 16 [bar] for SDR11 fittings; 10 [bar] for SDR17 fittings

- Work pressure gas systems: 10 [bar] for SDR11 fittings; 5 [bar] for SDR17 fittings

Product dimensions SDR17

D1 [mm] L1 [mm] C [mm] S1 Weight [kg] 63 66.5 129.5 3.8 0.18 75 75 150 4.5 0.30 90 80 130 5.4 0.36 110 94 209 6.6 0.94 125 92 163 7.4 0.89 140 95 241 8.3 1.64 160 100 189 9.4 1.64 180 111 211 10.7 2.35 200 121 231 11.9 3.47 225 127 251 13.2 4.5 250 134 382 14.8 9.83 280 154 430 16.6 13.71 315 153 465 18.7 19.35 SDR11

D1 [mm] L1 [mm] C [mm] S1 Weight [kg] 25 42.5 68.5 2.3 0.02 32 47 79 3 0.04 40 52 92.5 3.7 0.08 50 58.5 108.5 4.6 0.14 63 66.5 129.5 5.8 0.26 75 75 150 6.8 0.42 90 81 131 8.2 0.53 110 95 210 10 1.29 125 92 163 11.4 1.32 140 120 200 12.7 2.28 160 101 190 14.6 2.47 180 112 212 16.4 3.59 200 121 233 18.2 4.89 225 125 251 20.5 6.49 250 133 382 22.7 13.12 280 153 432 25.4 18.34 315 154 471 28.6 25.13 -

Certificates