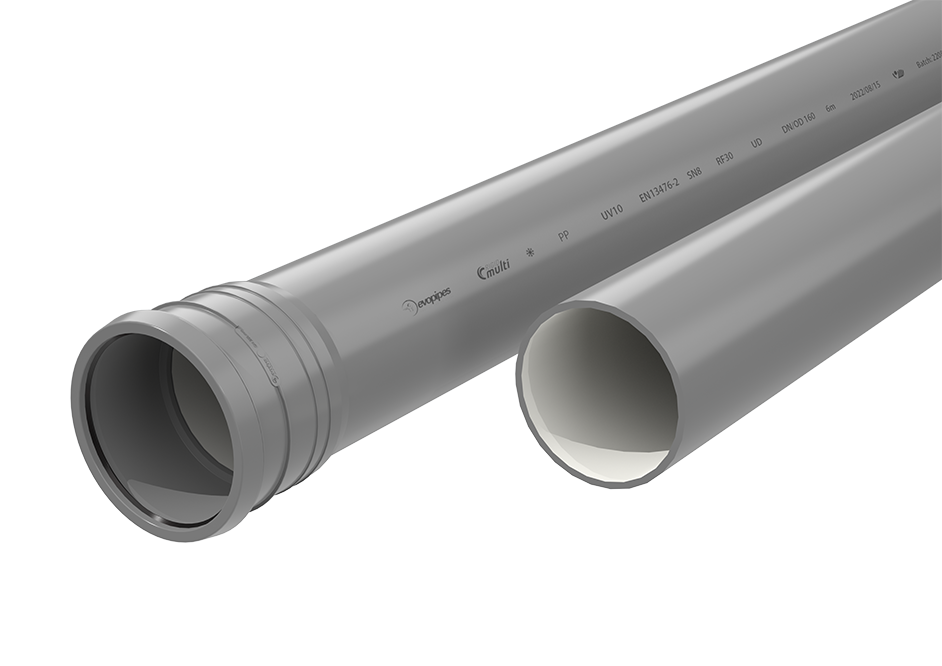

RIGID MULTI PP UV10

Smooth three-layer tubes, according to EN 13476-2 type A, DIN 4262-1

SN8 (kN/m²), DN/OD 110... 400 mm

RIGID MULTI PP UV10 is a system of smooth-walled pipes for drainage and drainage network systems of post-flow bridges made of polypropylene (PP) material. According to DIN 4262-1 classification, this pipe is type R3 - with a smooth wall surface. Designed for construction in direct sunlight - it is UV-stabilized.

It is possible to produce pipe in any color tone, according to customer wishes.

It is possible to produce pipe in any color tone, according to customer wishes.

- Standard pipe bar length 6 [m] (possible to order other lengths)

- Nominal ring stiffness class: SN8 [kN/m²]

- Available sizes: DN/OD 110, 160, 200, 250, 315 and 400 [mm]

- (UP) type - unperforated liquid transportation pipe

- Produced according to EN 13476-2, DIN 4262-1

-

Advantages

Good balance between product ring stiffness, ring flexibility and impact resistance

Ability to withstand overall sun radiation UV exposure > 700 Kl

Products are resistant to exposure to aggressive substances present in sewage and subsoil from pH2 (acidic medium) until pH12 (alkaline medium)

The products are environment-friendly and recyclable after several decades in operation

Long operational life - overs 50 years

-

Recommended application

Solutions for overpass drainage

Water drainage solutions for flyovers

RIGID MULTI PP UV10 can be constructed as a part of a drainage piping system - in places where it is necessary to create discharge outlet, as well as in places, where it is exposed to direct sunlight, for example, for bridge constructions and overpasses. The specially modified polypropylene material provides UV protection against solar radiation for a period of at least 10 years (UV radiation >700 kLy).

-

Technical information

RIGID MULTI UV10 pipes are being produced using three-layer technology where the inner and outer layer is produced using high-modulus polypropylene (PP) material, but the middle layer is from structured polypropylene (PP) material.

RIGID MULTI UV10 pipe is equipped with SEAL LOCK socket and integrated sealing ring¹. The supplied sealing ring grants a hermetic seal with a pressure rating of ≥0,5 bar (for the coupling area).

- Material: UV-stabilized polypropyene (PP)

- Produced according to DIN 4262-1, EN 13476-2

- Ring stiffness: SN8 [kN/m²]

- Ring flexibility RF30

- Impact resistance H50> 1.2 [m] (according to EN ISO 11173)

- Ability to withstand overall sun radiation UV exposure > 700 [Kly]

- Available sizes: DN/OD 110, 160, 200, 250, 315, 400 [mm]

¹ The sealing ring is resistant to oil according to the requirements of EN 681-2 p.5.10. Compliance is determined by the "Volume change in oil" test according to ISO 1817.

-

Certificates