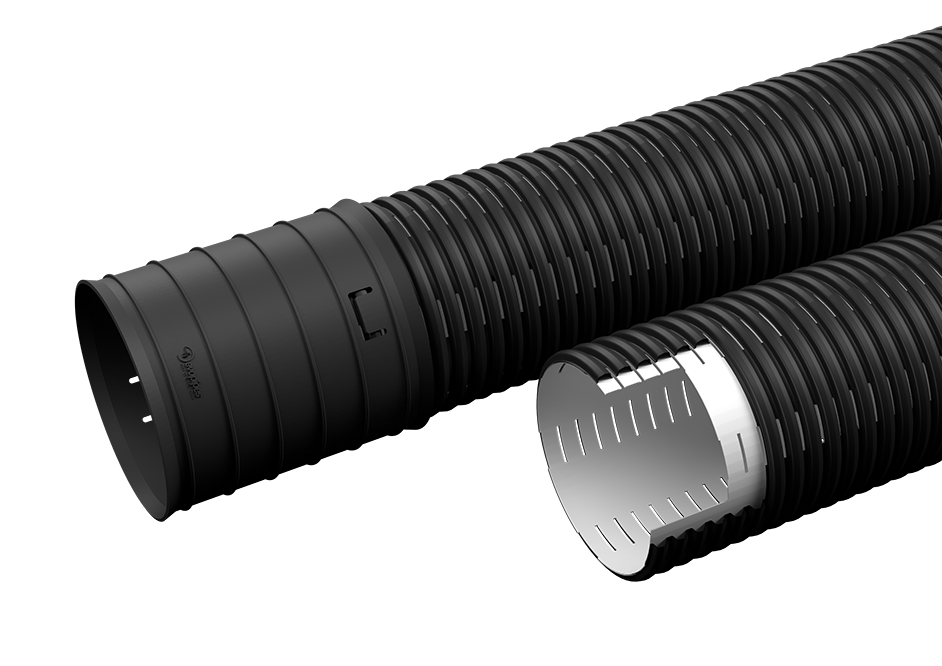

EVODRAIN HARD HDPE 360°

Totally perforated (TP) drainage pipe, DIN 4262-1

SN8 (kN/m²), DN/OD 63, 75, 90, 110, 125, 160 mm

EVODRAIN HARD are rigid drainage pipes made of high-density polyethylene (HDPE) material. Double-wall (R2 type) according to product standard DIN 4262-1- with corrugated (profiled) external wall and smooth internal surface.

- Nominal ring stiffness class SN8 [kN/m²]

- Water permeability ≥ 50 [cm2/m]

- Standard pipe bar length: 6 [m]

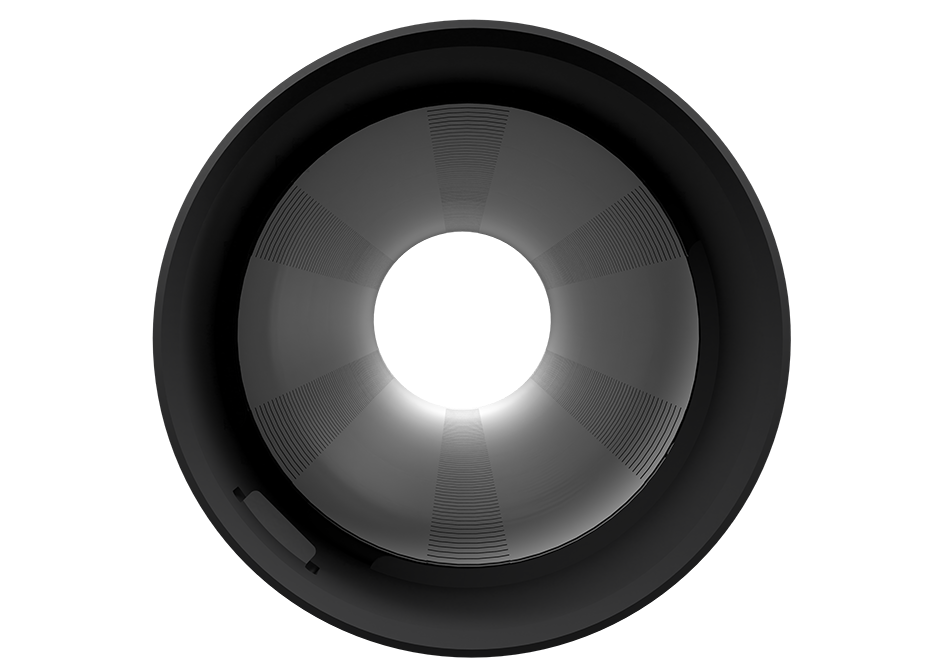

- (TP) type perforation: 360° totally perforated pipe with water inlet perforation openings evenly distributed around its ring

-

Advantages

Excellent impact resistance properties

Higher resistance against UV radiation

Chemical and biological inertness

Environmentally neutral material: PE is 100% recyclable and can be used repeatedly

Excellent long-term strength properties (service life up to 50 years)

-

Recommended application

Field drainage

For drainage on plots where the depth of groundwater deposition is less than the drainage norm, i.e. land plots for which, due to high groundwater levels, the topsoil is unable to drain excess moisture in the spring period, as well as due to high groundwater levels, underground engineering structures, roads, etc. are damaged.

Drainage system EVODRAIN HARD SN8 pipes are applicable for installations in:

In agriculture, forestry, in parks, squares and peat fields

Temporary and permanent drainage at construction sites

Stadiums and sport complexes

Pavements, pedestrian and bicycle paths

Landfills (liquid and biogas collection)

Road construction - with and without traffic load

-

Technical information

EVODRAIN HARD HDPE pipe is equipped with a double sleeve. The color of the outer surface of the pipe is black (RAL 9004) and the color of the inner surface is white.

- Produced according to DIN 4262-1

- Material: high-density polyethylene (HDPE)

- Ring stiffness SN8 [kN/m²]

- Resistance to external blows H50 > 1.2 [m] (according to EN ISO 11173)

- Available sizes DN/OD 63, 75, 90, 110, 125, 160 [mm]

- Standard pipe bar length: 6 [m]

It is possible to achieve a hermetic seal with a pressure rating of ≥0,5 bar (for the coupling area) by adding a rubber sealing ring. Oil-resistant¹ sealing rings are available on order, compliant with the requirements of EN 681-2 p.5.10.

¹ Compliance is determined by the "Volume change in oil" test according to ISO 1817.

Pipe dimensions Parameter DN/OD DN63 DN75 DN90 DN110 DN125 DN160 Inner Ø [mm] 51.7 62.7 76.2 94.1 106.7 137.6 Profile height [mm] 5.65 6.15 6.9 7.95 9.15 11.2 Length [m] 6 6 6 6 6 6 Perforation parameters Perf. length [mm] 13.2 13.3 13.2 9.2 10.1 11.2 Perf. width [mm] 1.2 1.2 1.4 1.2 1.2 1.4 Perforations per cross section 3 3 3 6 6 6 Permissible rinsing (cleaning) parameters:

- Maximum pressure: 120 [bar]

- Flow rate: 80 [l/min]

-

Certificates